Understanding the equipment and tools used in drilling rigs is essential for petroleum engineers and drilling engineers alike. These professionals rely on a wide array of specialized machinery and instruments to efficiently extract oil and gas from beneath the Earth’s surface. In this article, we will explore the various components of drilling equipment, from the rig itself to the tools used downhole.

What Is Drilling?

Drilling in the oil and gas industry is a process where a hole, called a wellbore, is made in the Earth’s surface to access underground reservoirs of oil or natural gas. This is done using a special machine called a drilling rig, which rotates a drill bit to break through layers of rock and soil.

The drill bit is attached to a long metal pipe called a drill string, which helps to carry drilling fluids down to the bit and bring up pieces of rock and soil as the hole gets deeper. Drilling allows oil and gas companies to extract these valuable resources from beneath the ground for various uses such as fuel and energy production.

What Is an Oil Rig?

An oil rig is a large structure with facilities to extract and process petroleum and natural gas that is used to drill for oil deep beneath the Earth’s surface, usually located in oceans or large bodies of water. It consists of a platform built on stilts or floats, which houses equipment and workers. The rig has a tall tower called a derrick, where the drilling equipment is located. From there, a long metal pipe called a drill string is lowered into the ground to extract oil from underground reservoirs. Oil rigs are crucial for finding and extracting oil to meet energy needs.

What Are The Main Systems Contained Within A Drilling Rig?

Understanding the key systems within a drilling rig is essential for comprehending its overall functionality and operation. Let’s deep dive into each of the components.

1. Hoisting System and Drawworks

The hoisting system and drawworks in a drilling rig are responsible for lifting and lowering the drill string and other tools into the wellbore. The drawworks consist of a large drum around which the drilling line is wound. This system also includes a set of brakes to control the speed and movement of the drill string.

2. Rotary System

The rotary system of a drilling rig facilitates the rotation of the drill string and the drill bit at the bottom of the wellbore. It typically consists of a rotary table or top drive, which provides the rotational force needed to turn the drill string. Additionally, the rotary system includes a kelly or a top drive system to transmit the rotational force from the rig to the drill string.

3. Circulation System

The circulation system is vital for circulating drilling fluids down the drill string and back up to the surface. It includes components such as mud pumps, which pump drilling mud from the mud pits into the drill string, and mud tanks, which store and condition the drilling fluid before it is pumped downhole. The circulation system also includes various valves and manifolds to control the flow of drilling fluids.

4. Power System

The power system of a drilling rig provides the necessary energy to operate various components of the rig. It typically includes diesel engines or electric motors that power the drawworks, mud pumps, and other equipment on the rig. Additionally, the power system includes generators to produce electricity for lighting, heating, and other electrical systems on the rig.

5. Safety and Blowout Prevention System

Safety is paramount on a drilling rig, and the blowout prevention system is designed to prevent uncontrolled releases of oil or gas from the well. This system includes blowout preventers (BOPs), which are large valves installed on the wellhead to seal the wellbore in case of a kick or blowout. The safety system also includes various alarms, sensors, and emergency shutdown mechanisms to protect personnel and equipment in the event of an emergency.

What Equipment Is Used in Drilling?

Drilling tools are the various types of equipment used to dig into the ground during drilling operations. These tools include machinery and serve a specific purpose in the drilling process.

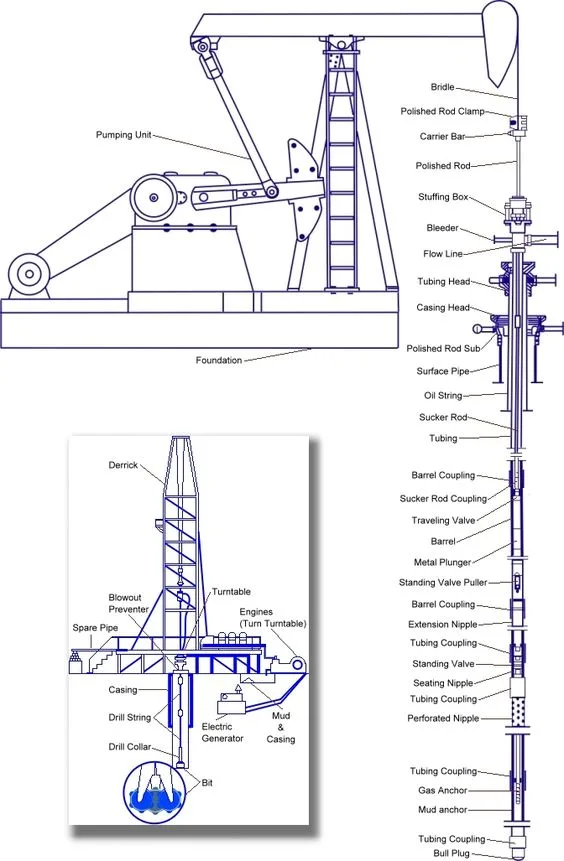

1. Bridle

The bridle is a device used to support and distribute the weight of the polished rod, reducing stress on the surface equipment.

2. Polished Rod Clamp

This clamp secures the polished rod in place to prevent it from moving during operation.

3. Carrier Bar

The carrier bar holds the polished rod and sucker rods in alignment, ensuring smooth and efficient operation.

4. Polished Rod

The polished rod is a long, smooth rod that connects the pumping unit on the surface to the downhole pump, transmitting power from the surface to the pump.

5. Stuffing Box

The stuffing box seals around the polished rod to prevent leakage of well fluids to the surface.

6. Bleeder

A bleeder is a valve used to release excess pressure from the stuffing box, preventing damage to the equipment.

7. Flow Line

The flow line is a pipeline that carries produced fluids from the wellhead to the production facility.

8. Tubing Head

The tubing head is a component installed on top of the casing head that provides a housing for the tubing and seals the annulus between the tubing and casing.

9. Casing Head

The casing head is a component installed at the top of the well casing, providing a means to suspend and seal the casing in the wellbore.

10. Polished Rod Sub

The polished rod sub connects the polished rod to the sucker rods, transmitting power from the surface to the downhole pump.

11. Surface Pipe

The surface pipe is a section of pipe installed at the surface to provide structural support for the wellhead equipment.

12. Oil String

The oil string is a tubing string used to produce oil from the reservoir to the surface.

13. Sucker Rod

Sucker rods are long, threaded rods used to transmit the pumping motion from the surface to the downhole pump.

14. Tubing

Tubing is a series of connected pipes that convey fluids from the downhole pump to the surface.

15. Barrel Coupling

Barrel couplings are fittings used to connect two sections of tubing or sucker rods.

16. Sucker Rod Coupling

Sucker rod couplings are fittings used to connect two sections of sucker rods.

17. Traveling Valve

The traveling valve is a valve that moves up and down inside the pump barrel, allowing fluid to flow into the pump during the upstroke and out of the pump during the downstroke.

18. Barrel

The barrel is the cylindrical section of the pump where the plunger moves up and down to create suction and lift fluid to the surface.

19. Metal Plunger

The metal plunger is a solid rod that moves up and down inside the pump barrel, creating suction and lifting fluid to the surface.

20. Standing Valve Puller

The standing valve puller is a tool used to remove the standing valve from the pump during maintenance operations.

21. Extension Nipple

An extension nipple is a short section of pipe used to extend the length of a tubing string.

22. Tubing Coupling

Tubing couplings are fittings used to connect two sections of tubing.

23. Standing Valve

The standing valve is a valve located at the bottom of the pump barrel that allows fluid to enter the pump during the upstroke.

24. Seating Nipple

The seating nipple is a component installed in the tubing string that provides a seat for the standing valve.

25. Perforated Nipple

The perforated nipple is a section of tubing with holes drilled into it to allow fluid to enter the tubing string from the surrounding formation.

26. Gas Anchor

A gas anchor is a device used to separate gas from liquid in the tubing string, preventing gas lock and improving pump efficiency.

27. Mud Anchor

A mud anchor is a device used to separate mud or solids from liquid in the tubing string, preventing plugging and pump damage.

28. Bull Plug

A bull plug is a threaded plug used to seal off the end of a tubing string or casing string.

In conclusion, drilling tools and equipment plays a crucial role in the process of extracting oil and gas from beneath the Earth’s surface. Each component, from the drilling rig to the various tools and parts used downhole, works together to efficiently and safely access valuable resources. Understanding the function and importance of drilling equipment is essential for those involved in the oil and gas industry.

Mastering the challenges of drilling is equally important to ensure successful operations. At PetroSync, we understand the significance of acquiring the necessary skills and knowledge in drilling. That is why we offer comprehensive drilling training courses designed to equip you with the expertise needed to excel in the field. Our courses cover various aspects of drilling operations, from equipment and techniques to safety protocols and industry best practices. With PetroSync, you can enhance your capabilities and advance your career in drilling.

(Credit: Oil and Gas Middle East)