Deepwater drilling involves drilling for oil or gas in water depths greater than 1,000 feet (about 305 meters). This type of drilling comes with unique challenges and requires special equipment and techniques. In this article, we will discuss how Deepwater drilling works, the differences from offshore drilling, the problems it faces, and the complexities engineers deal with in this environment.

What Is Deepwater Drilling?

The process of deepwater drilling, which involves creating holes in the Earth’s crust using a drilling rig for oil extraction under the deep sea, refers to drilling for oil or gas in deep ocean waters, typically exceeding depths of around 500 feet (150 meters). This type of drilling involves specialized equipment and techniques due to the challenging conditions present at such depths.

Engineers and drilling teams use advanced technology to reach and extract hydrocarbons from beneath the ocean floor, which requires careful planning, precise execution, and adherence to strict safety protocols. Deepwater drilling plays a crucial role in offshore oil and gas exploration and production, contributing significantly to global energy resources.

What Is Ultra Deepwater Drilling?

Ultra-deepwater drilling, which starts at water depths greater than 7,000 feet (2,134 meters), refers to the process of drilling for oil or gas in extremely deep ocean waters. This type of drilling requires advanced technology and equipment capable of withstanding high pressures and extreme conditions found at such depths.

Engineers and drilling teams use specialized rigs and tools to reach reservoirs located deep beneath the seabed. Ultra-deepwater drilling plays a critical role in offshore energy exploration and production, allowing access to untapped hydrocarbon reserves in deep ocean environments.

What Is The Deep Drilling Method?

The deep drilling method is a technique used to drill wells to significant depths below the earth’s surface, typically reaching thousands to tens of thousands of feet deep. This method involves using specialized drilling rigs and equipment designed to handle the challenges of drilling through deep layers of rock and sediment.

Engineers and drilling crews carefully plan and execute deep drilling operations, considering factors such as geological formations, wellbore stability, and pressure conditions deep underground.

Advanced technologies such as directional drilling and rotary drilling are often employed to navigate through various rock formations and maintain drilling efficiency. Deep drilling plays a crucial role in accessing valuable resources like oil, gas, geothermal energy, and scientific research into the earth’s subsurface.

What Is The Difference between Deepwater and Offshore?

Deepwater drilling is a subset of offshore drilling, distinguished by its operations taking place in water depths greater than 1,000 feet (about 305 meters). Offshore drilling, on the other hand, encompasses all drilling activities conducted in bodies of water, including seas or oceans, regardless of water depth. The distinction is significant as deepwater drilling presents unique challenges due to the greater depths involved compared to shallower offshore drilling.

How Does Deepwater Drilling Work?

Deepwater drilling works by using specialized equipment and techniques to extract oil and gas from beneath the ocean floor at water depths exceeding 1,000 feet (about 305 meters). The first step is lowering a drill bit down to start the hole, also called “spudding in” a well. The drill bit spins inside a casing that ensures the surrounding soft sediment doesn’t cave in. Here’s how it typically operates:

1. Platform Setup

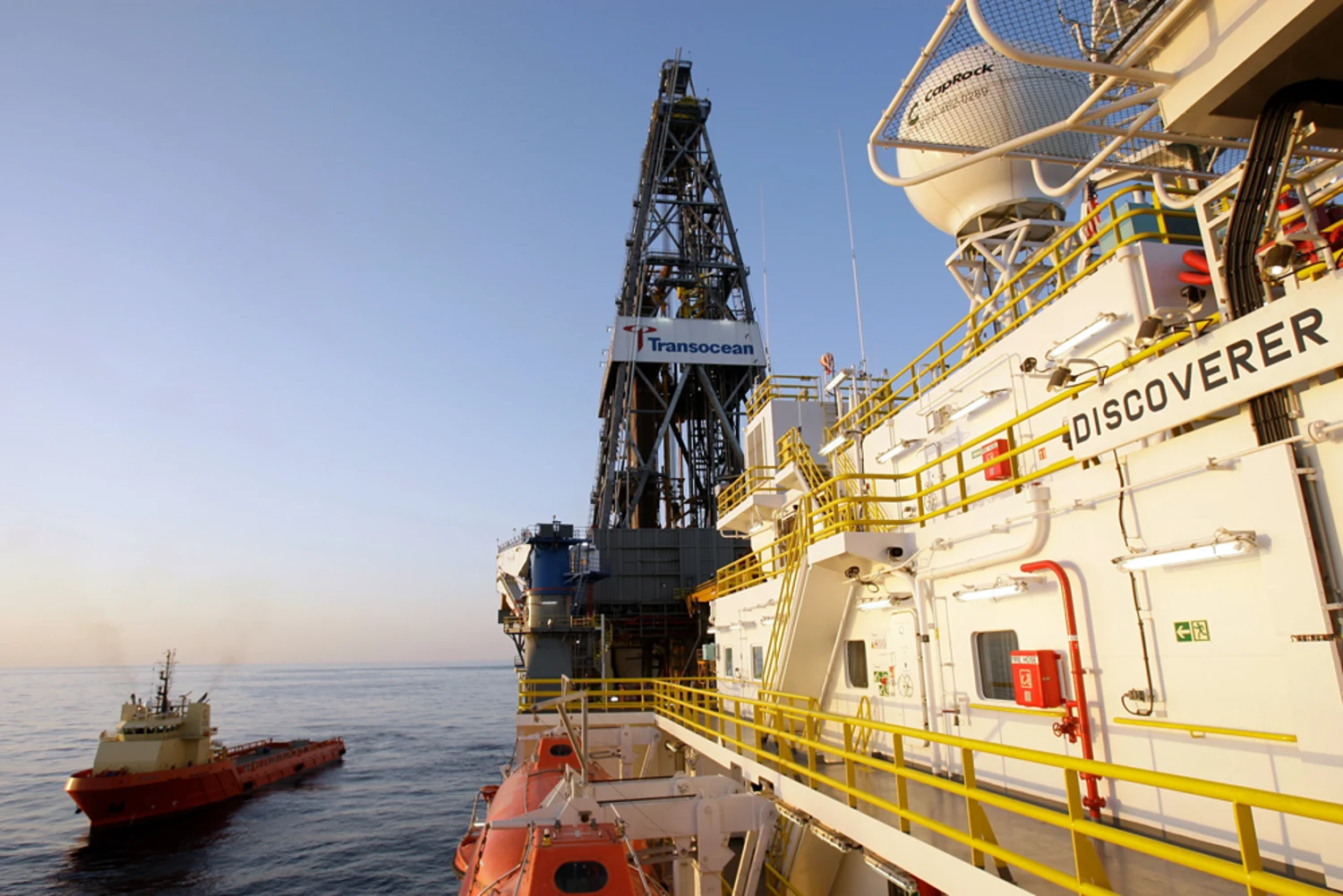

Deepwater drilling begins with setting up a drilling platform, which can be a floating vessel or a semi-submersible rig. These platforms are designed to remain stable in deep waters and withstand harsh ocean conditions.

2. Riser System

A riser system is used to connect the drilling platform to the wellhead on the ocean floor. The riser acts as a conduit for drilling fluids, tools, and equipment between the surface and the seabed.

3. Drilling Process

Once the setup is complete, drilling operations commence. A drill bit attached to a drill string is lowered through the riser to reach the seabed. The drill string is a series of connected pipes that transmit rotary motion and drilling fluid downhole.

4. Drilling Fluids

Special drilling fluids, known as mud, are circulated down the drill string and back up to the surface through the riser. Mud serves multiple purposes, including cooling the drill bit, carrying rock cuttings to the surface, maintaining pressure in the well, and stabilizing the borehole walls.

5. Wellbore Creation

As the drill bit rotates, it cuts through rock formations beneath the seafloor, creating a wellbore. The drilling mud helps to control pressure and prevent the formation of fluids (oil, gas, water) from escaping uncontrollably into the wellbore.

6. Casing and Cementing

Once a section of the wellbore is drilled, steel casing pipes are inserted and cemented in place to reinforce the well and prevent collapse. This process is repeated as drilling progresses deeper into the earth.

7. Completion and Production

After reaching the desired depth and completing the wellbore, additional equipment such as production tubing and downhole tools are installed to facilitate oil and gas production. The well is then tested and prepared for production operations.

8. Monitoring and Safety

Throughout the drilling process, engineers and technicians closely monitor various parameters such as pressure, temperature, and drilling fluid properties to ensure safe and efficient operations. Safety protocols and equipment, including blowout preventers (BOPs), are in place to manage unexpected well control situations.

Deepwater drilling involves advanced technology, stringent safety measures, and skilled personnel to overcome the challenges posed by operating in deep offshore environments and extracting valuable hydrocarbon resources from beneath the ocean floor.

What Are The Problems with Deepwater Drilling?

Deepwater drilling presents several challenges due to the extreme conditions and depths involved.

1. High Pressure

One of the main problems is the high pressure encountered in deep water reservoirs, which can exceed the pressure tolerance of conventional drilling equipment. Managing and controlling this high pressure is crucial to avoid well-blowouts and other safety risks.

2. Drilling Operation Complexity

Another issue is the complexity of drilling operations in deep water. The depth and harsh ocean environment make drilling and maintaining equipment more difficult compared to shallow water or land drilling. This complexity requires specialized equipment, skilled personnel, and rigorous safety protocols.

3. Lost Circulation

Lost circulation is another significant problem encountered in deepwater drilling. This issue is exacerbated by several factors specific to deepwater operations. One of these factors is the narrow operational bottom hole pressure (BHP) window, which refers to the range of pressures within which drilling operations can be safely conducted. In deepwater drilling, maintaining this narrow window becomes more challenging due to the high-pressure gradients encountered at greater depths.

Additionally, deepwater drilling faces challenges related to the low rock strength found in shallow sediments. These formations can be prone to fracturing and crumbling during drilling, leading to lost circulation issues where drilling fluids escape into these porous and weak zones instead of circulating properly within the wellbore.

Another contributing factor to lost circulation is the use of a riser, which is a pipe that connects the drilling rig to the seabed and allows drilling fluids to return to the surface. The riser system introduces complexities in fluid dynamics and pressure management, increasing the risk of fluid losses during drilling operations.

4. Environmental Risk

Furthermore, deepwater drilling poses environmental risks. Accidental oil spills or leaks can have severe consequences on marine ecosystems and coastal regions. Preventing and mitigating such environmental impacts require stringent regulations, advanced technology for spill response, and environmental monitoring throughout the drilling process.

Deepwater drilling presents significant challenges and complexities that engineers must navigate with precision and expertise. The process involves advanced technology, specialized equipment, and rigorous safety protocols due to operating in deep offshore environments. Engineers face difficulties such as high pressures, extreme depths, and harsh ocean conditions, making deepwater drilling a tricky endeavor.

Overall, deepwater drilling demands meticulous planning, continuous monitoring, and quick problem-solving skills from engineers. Despite the challenges, successful deepwater drilling can unlock valuable energy resources, but it requires a careful balance of technical expertise and safety measures to navigate the complexities of deep-sea exploration and extraction.

Additionally, PetroSync offers a range of advanced drilling training programs tailored to enhance your skills and knowledge in dealing with complex drilling challenges. These programs include Advanced HPHT training, Stuck Pipe Prevention training, Advanced Well Log training, Applied Drilling Well Engineering Training, and Upstream Petroleum training. By enrolling in these courses, you can gain valuable insights and expertise to tackle the intricacies of drilling skills and other technical aspects of the oil and gas industry effectively.

Credit header image: media-cldnry.s

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.