In the world of oil and gas, evaluating reservoirs is vital for success. Cased hole logging is a critical tool in this process, helping us understand what’s beneath the surface. Before we dive into the details of cased hole logging and its role in reservoir evaluation, let’s first grasp why it’s so important. This introduction aims to explain why cased hole log matters in assessing reservoirs.

What Is A Cased Hole Log?

A cased hole log involves retrieving logging measurements through the well casing, or the metal piping that is inserted into the well during completion operations, and is a type of well log used in oil and gas exploration and production.

These measurements are taken after the well has been drilled and cased with steel tubing. Cased hole logs provide valuable information about the surrounding rock formations and fluids, aiding operators in making decisions about well performance, production strategies, and potential interventions to optimize production and maximize hydrocarbon recovery.

What Is an Open Hole in Casing?

An open hole in casing refers to sections of the wellbore, those where the wellbore is left uncased or partially cased from the reservoir section to the surface, where the casing, or the metal tubing inserted into the well, does not completely cover the surrounding rock formations.

Instead, the rock formations are left exposed or “open” without the protective barrier of the casing. This allows for direct contact between the wellbore and the formations, which can be advantageous for certain operations such as logging or well testing. However, it also poses risks such as instability or fluid migration if not properly managed.

What Is The Difference Between Cased and Open Hole Logging?

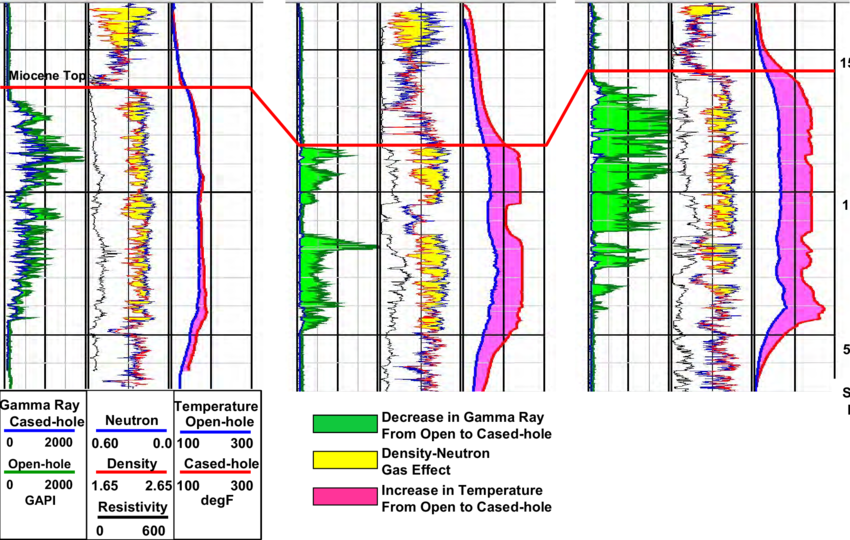

Cased hole logging and open hole logging are two methods used to gather information about the subsurface formations in oil and gas wells, but they differ in the conditions under which they are performed.

Cased hole logging involves running instruments down the wellbore after the well has been drilled and cased with steel tubing. This method is used when the well has been completed and the casing is in place. Cased hole log provides information about the condition of the casing, as well as the formations surrounding it.

On the other hand, open hole logging is conducted before the well is cased or after the casing has been removed or perforated in certain sections. This method allows for direct measurements of the formations without the obstruction of the casing. Open hole logging provides detailed information about the properties of the formations, which can be valuable for reservoir evaluation and well planning.

|

Open hole |

Cased Hole |

| Better Data Quality | Not using valuable rig time |

| Fewer Environmental Effects | Much lower risk of tool loss including radioactive sources |

| More Measurement Choices | Ease of deployment |

| Completion Decision Prior to Setting Casing | Use of tractors in high angle and horizontal wellbores |

In summary, the main difference between cased hole and open hole logging lies in the presence or absence of casing in the wellbore at the time of logging, with each method offering unique advantages depending on the stage of well construction and the objectives of the logging operation.

What Are The Use of Cased Hole Logging?

Cased hole logging is used for several purposes in oil and gas wells:

1. Downhole Flow

Cased hole logging helps measure the flow of fluids within the wellbore. By analyzing the responses of logging tools, operators can determine the presence, type, and movement of fluids such as oil, gas, and water in the well. This information is crucial for evaluating reservoir productivity and optimizing production strategies.

2. Casing Condition

Cased hole logging allows for the assessment of the condition of the casing, or the metal tubing inserted into the well. It helps identify any defects, corrosion, or damage to the casing that could compromise well integrity or lead to fluid leaks. By detecting issues early, operators can take preventive measures to maintain the structural integrity of the wellbore.

3. Cement Integrity

Another important use of cased hole logging is to evaluate the integrity of the cement sheath surrounding the casing. Proper cementing is essential for isolating the wellbore from surrounding formations and preventing fluid migration between different zones. Case hole logging helps identify any gaps, channels, or other defects in the cement, allowing for remedial action if needed to ensure zonal isolation and wellbore integrity.

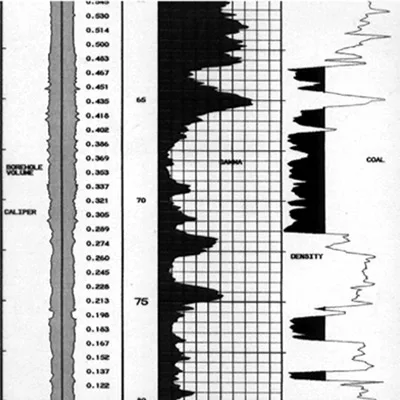

4. Formation Properties

Case hole logging also provides valuable information about the properties of the formations surrounding the wellbore. By analyzing the responses of logging tools to various formations, operators can characterize lithology, porosity, permeability, and other reservoir properties. This information aids in reservoir evaluation, hydrocarbon resource assessment, and well planning, helping operators make informed decisions about production and reservoir management strategies.

In summary, cased hole log plays a critical role in evaluating downhole flow, assessing casing condition and cement integrity, and characterizing formation properties. These insights are essential for optimizing well performance, ensuring wellbore integrity, and maximizing hydrocarbon recovery in oil and gas production operations.

In conclusion, cased hole logging plays a crucial role in oil and gas exploration and production. By providing valuable insights into downhole flow, casing condition, cement integrity, and formation properties, cased hole logging enables operators to make informed decisions about well performance, integrity, and productivity.

The ability to assess these factors accurately and efficiently is essential for optimizing production, ensuring wellbore integrity, and maximizing hydrocarbon recovery. As such, this logging is an indispensable tool for maintaining operational efficiency, minimizing risks, and ultimately achieving success in oil and gas operations.

As you’ve discovered the critical role of cased hole logging in ensuring well integrity and optimizing production in oil and gas operations, it’s essential to deepen your understanding through specialized training. PetroSync offers a comprehensive Well Integrity Cased Hole Logging Interpretation course designed to equip you with the knowledge and skills needed to interpret case hole logging data effectively.

By enrolling in this training, you’ll gain insights into advanced techniques for assessing well integrity, analyzing formation properties, and making informed decisions to optimize well performance. Don’t miss this opportunity to enhance your expertise and stay ahead in the industry. Join us for the Well Integrity Cased Hole Logging Interpretation training with PetroSync.

Credit header image: Research Gate / Terence O’Sullivan

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.