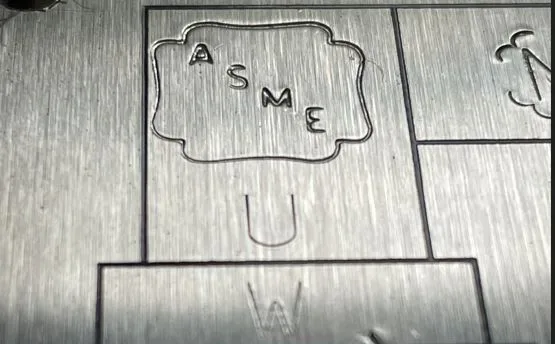

In the field of industrial quality assurance, ASME U Stamp and R Stamp play crucial roles. In this article, we unravel the complexities of these certifications and get to know the significance in maintaining top-notch standards for pressure vessels and related equipment by using ASME stamp.

What Is ASME Stamp?

The ASME Stamp is a significant indicator to regulators, customers, and industries, showcasing your organization’s dedication to quality and safety. It serves as a permission slip, enabling manufacturers to produce pressure-retaining parts, power boilers, and power piping in compliance with ASME standards. In essence, it’s a mark of commitment to upholding high standards in the fabrication of crucial industrial components.

What Is ASME R Stamp?

The ASME R Stamp is a credential granted by The National Board of Boiler and Pressure Vessel Inspectors. This stamp signifies approval for the alteration or repair of steam boilers.

Essentially, it authorizes individuals or organizations to conduct repairs and modifications on pressure-retaining equipment, such as pressure vessels and boilers. This certification ensures that capable fabricators, able to meet the code requirements, exclusively perform such alterations or repairs.

What are The Requirements and Application Process of R Stamp?

Repair organizations seeking the R Stamp must demonstrate proficiency in welding, materials, and inspection techniques. The application process involves submitting documented procedures, qualifications of personnel, and examples of previous repair work. Rigorous audits follow to verify compliance.

What Are The Importance of Repairs and Alterations of R Stamp?

The R Stamp is crucial for organizations engaged in the repair and alteration of pressure vessels. It certifies that repairs meet or exceed original construction standards, assuring clients and regulatory bodies that the vessel remains safe and reliable post-repair.

What Is ASME U Stamp?

The ASME U Stamp is a certification that confirms a manufacturer’s adherence to the quality control system requirements outlined in the American Society of Mechanical Engineers ASME Boiler and Pressure Vessel Code (BPVC). When a manufacturer possesses this stamp, it signifies their authorization to undertake the design, fabrication, inspection, and testing of unfired pressure vessels. In essence, it’s a mark of approval, indicating that the manufacturer meets the specified standards for ensuring the quality and safety of these pressure vessels.

How Is The Application Process of U Stamp?

Getting the ASME U Stamp involves a meticulous application process. Manufacturers must submit design specifications, and fabrication details, and demonstrate the capability to meet ASME standards. Rigorous inspections follow, ensuring that the pressure vessels meet or exceed the required quality benchmarks.

What Are The Key Requirements of U Stamp?

Manufacturers must meet specific requirements, including material specifications, welding procedures, and non-destructive examination methods. These criteria guarantee the structural integrity and safety of the pressure vessels, instilling confidence in end-users and regulatory authorities.

What Are The Benefits of U Stamp for Manufacturers

The U Stamp opens doors to global markets, enhancing a manufacturer’s credibility and competitiveness. Clients often prioritize suppliers with the U Stamp, recognizing the commitment to quality and safety. It’s a strategic investment that pays dividends in market access and reputation.

What Is ASME S Stamp?

The ASME S Stamp is a notable certification that enables companies to manufacture power boilers, power pipelines, and ASME Pressure Retaining Parts following the guidelines outlined in Section I of the latest edition of the ASME Boiler and Pressure Vessel Code. Essentially, it grants authorization for the production of specific industrial components, ensuring compliance with the relevant standards and codes set by the American Society of Mechanical Engineers (ASME).

How Are The Application Process and Qualifications of S Stamp?

Obtaining the S Stamp requires manufacturers to demonstrate expertise in materials, welding, and fabrication. The application process includes detailed submissions on design specifications, materials, and quality control procedures. Rigorous audits follow to verify compliance.

What Is The Importance of S Stamp in the Boiler and Pressure Vessel Industry?

The S Stamp is a badge of honor in the boiler and pressure vessel industry. It assures customers that the equipment meets the highest safety and performance standards. Manufacturers holding the S Stamp contribute significantly to ensuring public safety through reliable and compliant equipment.

How Can S Stamp Ensure Public Safety?

The S Stamp is pivotal in ensuring public safety by guaranteeing that power boilers and pressure vessels are manufactured to withstand extreme conditions. It guarantees end-users, regulatory authorities, and the general public that the equipment is built to the highest safety standards.

In conclusion, the ASME U, R, and S Stamps play pivotal roles in ensuring the quality, safety, and compliance of pressure vessels within the oil and gas industry. These certifications collectively elevate industry standards, providing engineers in the oil and gas sector with reliable benchmarks for quality assurance and regulatory compliance.

If you are an engineer aspires to advance your career and uphold the highest industry standards, investing in ASME Section VIII Div 1 and 2 training and API 510 training by PetroSync is a strategic choice. It not only aligns with ASME certifications but also opens pathways for career growth in the dynamic oil and gas sector.

Credit: Aspire Energy

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.