High-Pressure High-Temperature (HPHT) oil wells are at the forefront of energy exploration, venturing into extreme conditions to extract valuable resources. Our article explores HPHT drilling, from its definition to the latest technological advancements related to HPHT in the oil and gas industry.

What Is The High Temperature and High-Pressure Well?

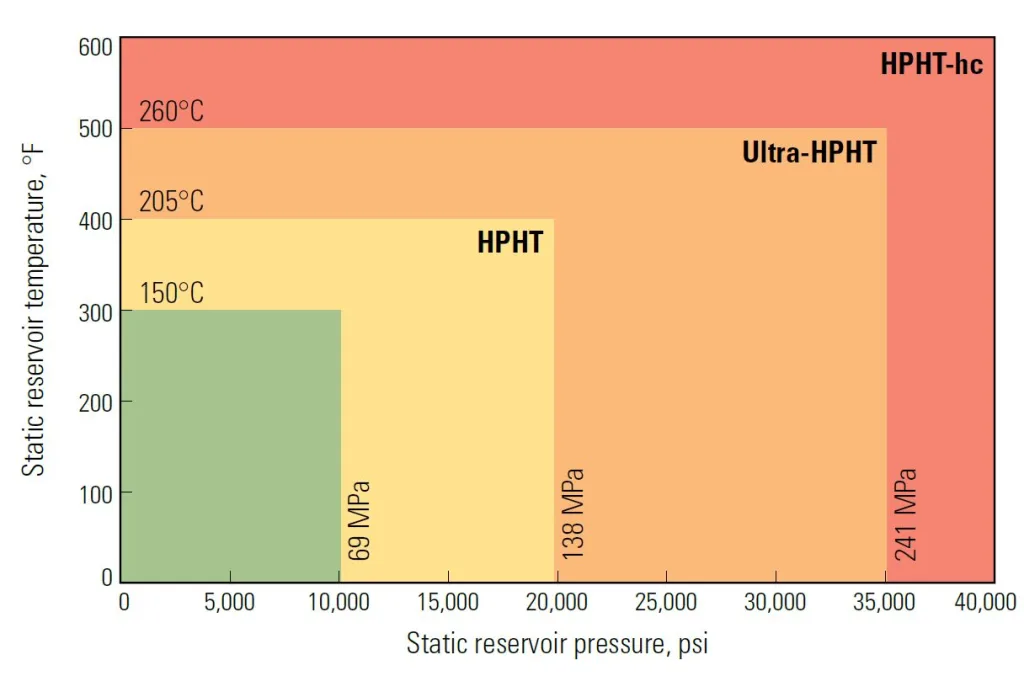

A high-temperature and high-pressure well, known as HPHT or High Pressure, High Temperature, is defined as those wells with a bottom hole temperature greater than 150°C (300°F) and requiring pressure control equipment with a rated working pressure exceeding 69 MPa (10,000psi).

In simple terms, these wells operate where the temperature and pressure are notably elevated. These challenging conditions require specialized equipment and techniques to ensure safe and efficient oil or gas extraction. Essentially, an HPHT well operates in more extreme settings compared to standard wells.

Wells classified as high-pressure, high-temperature (HPHT) pose significant challenges to operators and service companies. The term HPHT can be assigned to wells with either high pressure or high temperature—rarely both. Regardless of the designation, these wells present specific challenges that must be overcome for successful operations.

Overcoming these challenges involves addressing all aspects of well construction and production, requiring operators and service companies to adopt approaches that can differ significantly from those used in wells without extreme conditions. The specific approaches depend on the levels of pressures and temperatures encountered.

Once the expected pressures and temperatures are known, guidelines and operational plans can be developed to drill, assess, complete, and safely extract hydrocarbons.

What Are The Characteristics of HPHT Well?

The characteristics of an HPHT (High Pressure, High Temperature) well are based on specific criteria outlined by the American Petroleum Institute (API). According to API standards, a well qualifies as HPHT if it meets the following conditions:

1. Pressure Greater than 15,000 psi [103 MPa]

An HPHT well is one where the pressure exceeds 15,000 pounds per square inch (103 megapascals).

2. Temperature Above 350°F [177°C]

High temperature is considered when the well operates at temperatures higher than 350 degrees Fahrenheit (177 degrees Celsius).

3. Anticipated Surface Conditions

The completion and well control equipment must be rated above 15,000 psi, considering the expected surface conditions.

4. Anticipated Shut-In Surface Pressure

An HPHT well has an anticipated shut-in surface pressure exceeding 15,000 psi.

5. Flowing Temperature at the Surface Above 350°F

The flowing temperature at the surface is in excess of 350 degrees Fahrenheit.

These characteristics guide the design specifications for equipment, dictate acceptable materials for HPHT operations, and set standards for testing well control and completion hardware. Adhering to these criteria ensures the safety, suitability, and integrity of HPHT operations in the oil and gas industry.

What Is The Temperature Challenge in HPHT Well?

In high-pressure, high-temperature (HPHT) wells, managing downhole pressure, specifically pore pressure, is a critical aspect of drilling. Pore pressure refers to the pressure of fluids within the pores of reservoir rocks.

1. Challenges with Increasing Depth

As drilling depth increases, so does pore pressure due to the need for formations to support the overburden above them. To counteract increasing pore pressure and prevent fluid influx, engineers use a weighted drilling fluid.

Engineers carefully calculate the hydrostatic pressure created by the drilling fluid to balance the rising pore pressures. This balance is crucial to avoiding fluid influx into the wellbore during the drilling process.

2. Predicting Pore Pressure

Predicting pore pressure becomes challenging due to the variable nature of geologic features. Pressure gradients can change rapidly across faults and depleted reservoir zones, impacting downhole pore pressure.

Engineers compute downhole pore pressure using a hydrostatic gradient based on seawater weight. However, due to geological variations, higher hydrostatic pressure is often necessary to overcome reservoir pore pressure.

In HPHT wells, drilling mud with weights more than twice that of seawater is commonly used to manage the variable hydrostatic pressure requirements.

3. Managing Overpressured Formations

Overpressured formations, characterized by higher-than-normal pore pressure, may be present even at shallow depths, adding complexity to the drilling process.

4. Challenges in Ultradeep Wells

Ultradeep wells, reaching depths beyond 10,700 m, pose additional challenges with hydrostatic pressure exceeding 207 MPa (30,000 psi).

To address extreme pressures, design engineers focus on metallurgy and sealing. Materials must withstand high pressure, often under high temperatures, and endure multiple pressure cycles without failing.

5. Risks Beyond Equipment

The risks associated with downhole pressure extend beyond equipment considerations. High-pressure operations at the surface pose a risk potential to personnel. To manage the risk, engineers design equipment that functions above the anticipated maximum pressure. The full system’s maximum pressure depends on the lowest rated component in the containment string.

Material selection, thickness, elastomer configuration, sealing mechanisms, and pressure control components are influenced by the full system’s maximum pressure to ensure safe and successful operations.

In summary, the temperature challenge in HPHT wells involves carefully managing downhole pressure, predicting pore pressure, and selecting materials that can withstand extreme conditions. These considerations are vital for ensuring the safety and success of drilling operations in high-pressure, high-temperature environments.

What Is The Pressure Challenge in HPHT Well?

In high-pressure, high-temperature (HPHT) wells, the pressure challenge is a critical aspect influenced by both natural conditions and external factors. Understanding and managing downhole pressure is crucial for safe and effective drilling operations.

1. Geothermal Gradient and Depth

The Earth’s geothermal gradient, which averages about 1.4°F/100 ft [2.55°C/100 m], impacts downhole temperatures. To reach the 350°F threshold, a well depth exceeding 19,700 ft [6,000 m] is typically required. However, downhole temperatures are often affected by natural conditions or external influences.

2. Localized Geothermal Hotspots

Proximity to localized geothermal hotspots can quickly elevate downhole temperatures encountered during drilling. Steam injection, commonly used for heavy oil production at shallow depths, can significantly increase downhole temperatures.

3. Geothermal Gradients in Deep and Ultra Deep Waters

Wells drilled in deep and ultradeep waters often have geothermal gradients lower than the Earth’s average. Consequently, deepwater wells frequently experience high pressure and temperatures below the high-temperature threshold.

Mitigating high temperatures depends on the operation type and the equipment used. Wireline and Logging While Drilling (LWD) tools are designed with electronics suitable for high-temperature environments.

Temperature barriers like Dewar flasks can be placed around tools, although time constraints limit their usage. Sealing elements in tools use temperature-resistant elastomers.

Temperature Considerations for LWD Operations

Tools used for LWD operations generally have lower temperature ratings than those for wireline operations. Continuous circulation of drilling fluids through the Bottom Hole Assembly (BHA) exposes tools to lower temperatures than in the formation. In extreme cases, drilling fluids may be cooled before circulating downhole to protect sensitive BHA components.

Use of Oil-Base Mud (OBM) Systems

Most high-temperature wells are drilled using oil-base mud (OBM) systems. Special high-temperature OBM systems have been developed to retain mud rheological properties at elevated temperatures. However, a trade-off exists as OBM systems tend to result in higher downhole temperatures compared to water-base mud systems.

In summary, the pressure challenge in HPHT wells involves navigating the complex interplay of geothermal gradients, proximity to hotspots, and the choice of drilling fluid systems. Engineers must employ mitigation techniques and select appropriate tools to ensure safe and successful drilling operations in high-pressure, high-temperature environments.

In conclusion, working in High Pressure, High Temperature (HPHT) conditions demands special attention and careful consideration. Success in HPHT operations relies on having specialized equipment, the right tools, and thorough training. Planning ahead is crucial, and often, operational procedures need modification to effectively address the challenges posed by HPHT environments.

Unlike mistakes in conventional wells that might result in routine delays, errors in HPHT operations can lead to severe consequences for both equipment and personnel. Therefore, a high level of diligence is necessary to prevent such disasters.

Future – Proof Your Expertise – Join PetroSync’s Specialized Training

PetroSync, understanding the unique challenges posed by High Pressure, High Temperature (HPHT) conditions, stands ready to support you in the oil and gas industry. With a commitment to excellence, PetroSync offers advanced HPHT training and Applied Drilling Well Engineering Training.

These specialized training related to upstream skills are designed to equip you with the knowledge and skills needed to navigate the complexities of HPHT environments. By enrolling in PetroSync‘s training, you gain access to cutting-edge insights, advanced techniques, and industry best practices for handling high-pressure and high-temperature challenges.

Whether you are looking to enhance your expertise in well engineering, drilling operations, or overall HPHT management, PetroSync’s training programs are tailored to provide practical and applicable insights. The goal is to empower professionals like you to effectively address.

Results-oriented and thorough SEO specialist with extensive experience in conducting keyword research, developing and implementing digital website promotion strategies and plans, managing campaigns to develop company websites in the digital world, excellent knowledge of marketing techniques and principles, and attentive strong attention to detail.