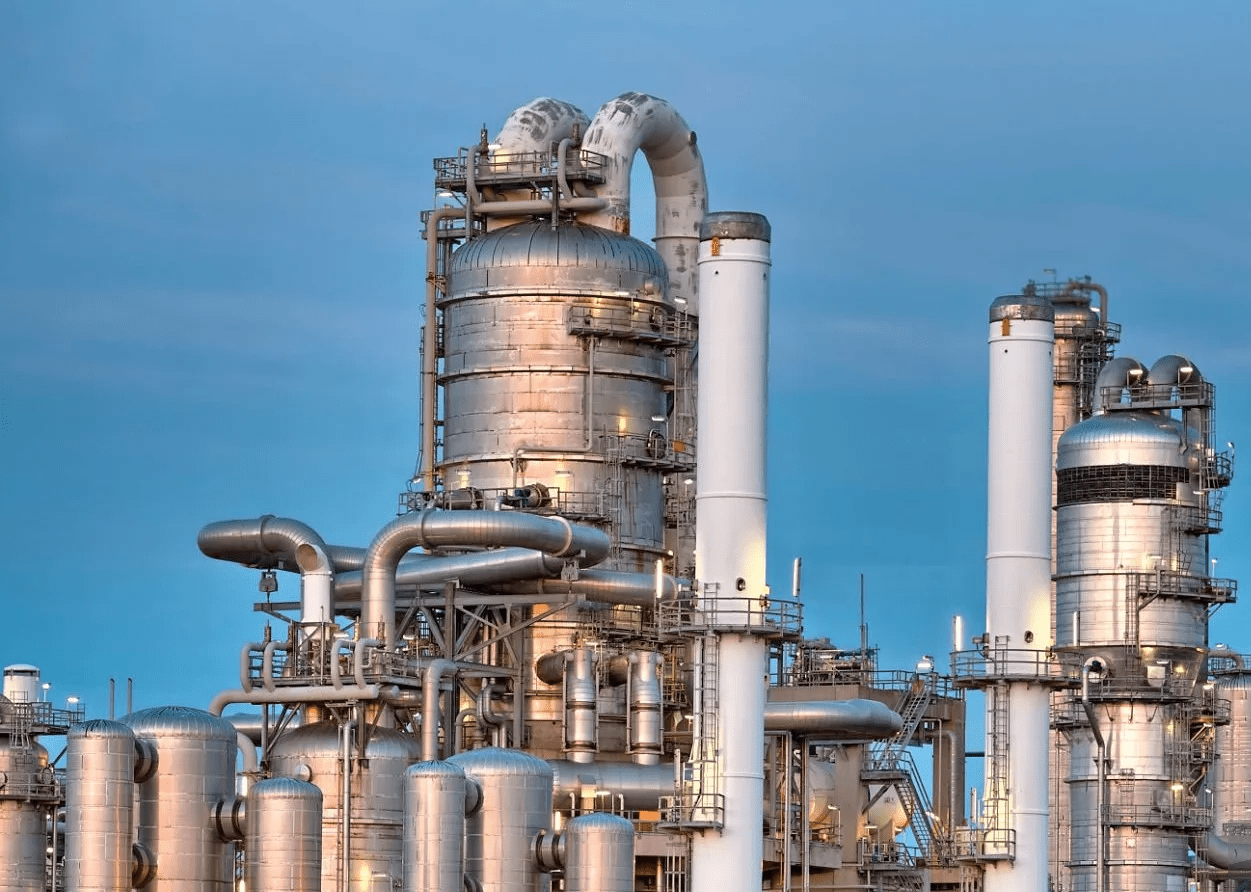

Let’s explore the significance of Fitness for Service and its established role in the oil and gas field. In the ever-changing industry landscape, maintaining high service quality is crucial for long-term success. This discussion will focus on the “Introduction to Three Levels of Fitness for Service Assessment,” emphasizing the importance of fitness at the individual, team, and organizational levels.

What Is Fitness For Service?

Fitness for Service is an assessment carried out using the best-practice industry standards. In straightforward terms, it refers to the evaluation process used to determine whether an industrial asset, such as equipment or infrastructure, is still fit to perform its intended function.

The FFS assessment involves examining factors like structural integrity, material conditions, and operational history to ensure the asset’s continued safe and effective operation. Essentially, it is a way to check if the asset is in good enough condition to do its job without compromising safety or efficiency.

Fitness-for-service is crucial at different levels, from basic screenings to more in-depth evaluations. The first-level assessments help decide if the equipment is suitable for continued use, especially when data is limited. This approach is a cost-effective way to save time and money that might be spent on fixing or replacing equipment.

While the second and third-level assessments are pricier due to requiring more data, they contribute to overall improvements in a power plant’s performance throughout its lifespan. Utilizing Fitness-for-Service assessments at various levels ensures heightened availability, reliability, efficiency, and safety within the power plant.

What Is Fitness For Service Assessment Level 1?

In simple terms, Fitness For Service Assessment Level 1 is the initial stage of evaluating whether an industrial asset, like equipment or infrastructure, is fit for continued operation. At this level, the assessment involves using primary data and straightforward calculations. It’s a quick and less complex process, utilizing tables and screening curves to determine if the asset is in suitable condition for its intended purpose. This level helps make initial decisions about the asset’s fitness for service without extensive data or advanced computations. Additionally, it is the most conservative and can be performed by an inspector or an engineer.

What Is Fitness For Service Assessment Level 2?

Fitness For Service Assessment Level 2 is the next step in evaluating the suitability of an industrial asset for continued operation. At this stage, the assessment becomes more detailed and involves more complex computations than Level 1.

If a Level 1 assessment indicates potential issues, Level 2 is initiated to delve deeper into the evaluation. This level often requires specialized software due to the intricacies of the computations involved. It aims to provide a more refined analysis, allowing a better understanding of the asset’s condition and the potential need for repairs or adjustments.

Level 2 assessments are typically conducted by experienced inspectors or engineers. Level 2 is intended for qualified engineers and requires simple data and analysis, ensuring a thorough examination of the asset’s fitness for continued service.

What Is Fitness For Service Assessment Level 3?

Fitness For Service Assessment Level 3 is the advanced stage of evaluating the fitness of an industrial asset for continued operation. At this level, the assessment is the most detailed and requires considerable operational experience and extensive data.

When Level 2 assessments indicate the need for further investigation, Level 3 comes into play. This level aims to provide an even more nuanced understanding of the asset’s condition, especially in severe cases.

However, Level 3 assessments are rarely conducted due to the complexity and potential for errors. These assessments demand a high level of expertise and are typically undertaken by seasoned professionals with substantial experience in the field. It is an advanced assessment requiring detailed data, computer analysis, and considerable technical knowledge and expertise in FFS assessment procedures.

What Is The Checklist of Fitness for Service Assessment Based on API 579?

Starting a thorough Fitness for Service (FFS) assessment requires careful consideration and a well-structured checklist is crucial for a detailed and organized evaluation. The API 579 standard from the American Petroleum Institute provides a reliable guide for these assessments, giving clear guidelines on determining the fitness of industrial assets.

Fitness for Service Assessment Procedure based on API 579 |

||

| Flaw and Damage Mechanism Identification |

|

|

| Applicability and Limitations of the FFS Assessment Procedures | Each section outlines when and how the assessment procedure should be applied, along with its constraints. A decision on whether to proceed with the assessment can then be made based on this information. | |

| Data Requirements |

|

|

| Assessment Techniques and Acceptance Criteria | Each section contains methods for assessing and criteria for accepting the evaluation results. If there are several types of damage, you might need to use multiple sections for a comprehensive assessment. | |

| Remaining Life Evaluation |

|

|

| Remediation | Each section outlines methods for addressing issues based on the specific type of damage or flaw. Remediation techniques may be employed to manage and mitigate potential damage linked to flaw growth or material deterioration. | |

| In-Service Monitoring | Each section details approaches for monitoring equipment during operation, depending on the type of damage or flaw. In-service monitoring is applied when it’s challenging to accurately establish remaining life and inspection intervals due to complexities within the service environment. | |

| Documentation |

|

|

To sum it up, going through the Fitness for Service assessments, especially with the three-level approach, is crucial for ensuring industrial equipment stays safe and effective. Whether a quick check or a detailed evaluation, each level helps us understand how well things are working and what needs attention. This not only keeps things running smoothly but also helps avoid potential issues.

Further, suppose you want to boost your skills in API 579 Fitness for Service assessments. In that case, PetroSync has an API 579 training program that breaks down the complexities, making it easier for you to ensure that equipment stays in top-notch condition. So, take the next step in enhancing your knowledge with PetroSync’s API 579 Fitness for Service training.

Credit header image: freepik

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.