Brittle fracture has been a constant concern in many industries, like construction and materials science. Knowing what makes brittle fractures happen and how to stop them is essential to keep things safe and reliable. In this article, we will explore brittle fractures, from what they are to how to prevent them best.

What Is a Brittle Fracture?

A brittle fracture, characterized by the sudden or rapid break of a component under stress without undergoing any noticeable permanent deformation or ductility, is a type of material failure. This fracture typically occurs in hard materials such as ceramics, some metals, glasses, and specific polymers. When a brittle fracture happens, the material shatters abruptly, and the broken pieces can often be reassembled without any significant change in their original shape or dimensions.

What Are Brittle Fracture Characteristics?

Brittle fractures are typically identified by their minimal or absent plastic deformation before they break. As mentioned previously, materials prone to brittle fractures include glasses, ceramics, some polymers, and specific metals. In certain situations, metals typically known for their ductility can experience brittle failures, potentially resulting in severe consequences.

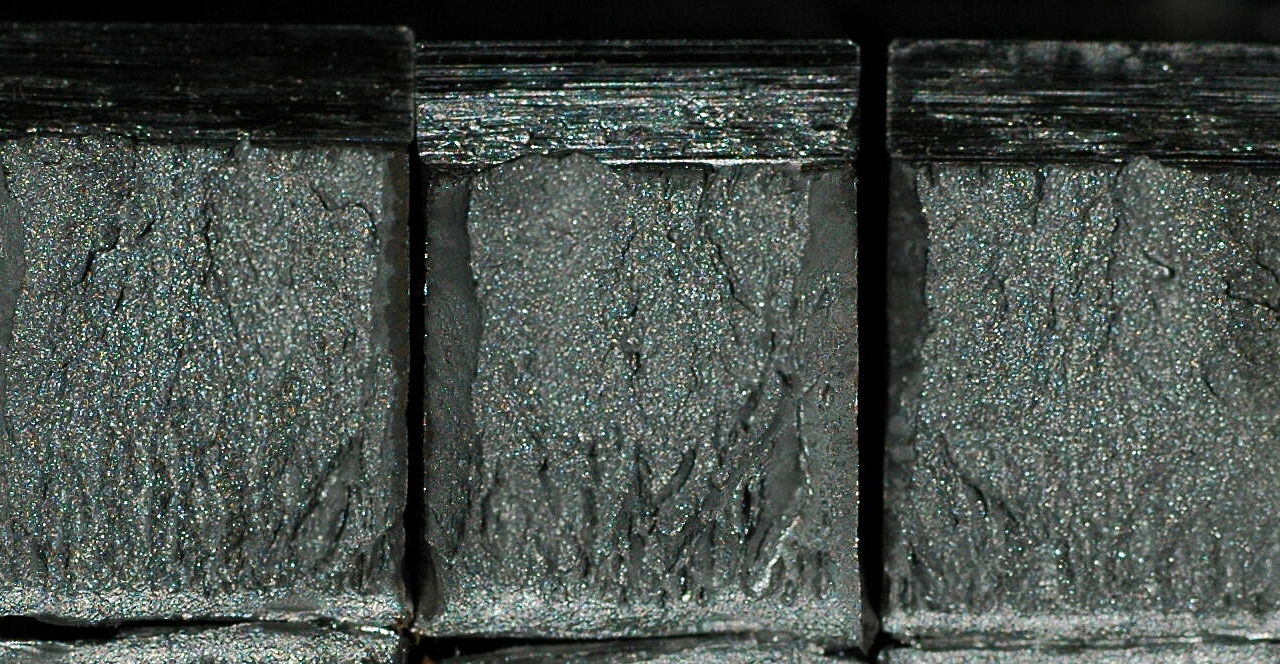

Similar to ductile fractures, brittle fractures also exhibit a distinct surface appearance. The surface of a brittle fracture is usually relatively smooth, and the crack advances through the material through a process known as cleavage.

What Factors Contribute to Brittle Fracture?

Several factors contribute to brittle fracture. These factors encompass various aspects of materials and conditions, all of which can influence the propensity for brittle fracture.

1. High Residual or Applied Stress

Residual stress is the internal stress within a material, often caused by manufacturing processes like heat treatments, welding, and cold working, where the material is deformed or strained. Imagine a scenario where a cast iron housing cracked during machining. The crack’s opening and lateral movement signaled the presence of significant residual stress that had been in the material since it was cast. On the other hand, applied stresses result from external loads during the component’s use.

2. Low Fracture Toughness

Low fracture toughness can contribute to brittle fracture because it means that a material does not need a lot of energy to break. In other words, it fractures easily without significant deformation or absorbing much energy. When a material has low fracture toughness, it is more prone to sudden, catastrophic failure without warning, which is a characteristic of brittle fractures.

3. The Presence of A Crack-like Flaw or Defect within The Material

Crack-like flaws or notches in a material can cause areas of concentrated stress. Some materials are more likely to experience brittle fracture when these notches are present. This tendency is often called “notch sensitivity,” meaning the material can break more easily with these notches or cracks.

4. Reduced Grain Size

When the grains in a material become smaller, they tend to break in a more brittle way. This happens because, in smaller grains, there isn’t much room for dislocations to move before they bump into grain boundaries and stop. When dislocations can’t move far, the material can’t deform as much before it breaks, making the fracture more brittle.

5. Low Temperatures

Another critical factor that can lead to brittle fracture is temperature. When the temperature is low, the atoms in the material vibrate less and have limited movement, making the material more likely to break in a brittle way.

6. High Strain Rates

The speed at which a material is loaded and deformed can influence how it fractures. In situations where the strain rates are extremely high, like during an impact, even materials that are usually ductile can break in a brittle manner.

7. Section size

The thickness of a material that experiences loading, causing it to break, can influence how the fracture happens. When a material is loaded, it gets deformed in three different directions. For instance, in a test where a square bar is pulled, it stretches in the direction of the applied force. In the other two directions, the sides of the bar get compressed, which is known as the Poisson effect.

In a narrow material under load, the deformation can spread across the total thickness, showing ductile behaviour. As the material’s thickness increases, the deformation depth remains somewhat constant. In the central part of the material, where it is thick, the fracture often exhibits typical brittle fracture characteristics, appearing as a flat fracture surface perpendicular to the direction of the load. This is sometimes called shear lips and is associated with brittle fractures.

8. Microstructure

In the case of iron alloys like steel, they can change into martensite when they are quickly cooled down after being exposed to high temperatures. Martensite is a kind of structure that’s not entirely stable and, in steel, it is a super-concentrated mix of carbon and iron. Because the cooling process is so rapid, it creates a lot of stress on the material. This high stress makes the steel very hard and strong but also makes it more brittle.

How To Avoid Brittle Fracture?

To avoid brittle fractures, you can take several precautions. These actions are crucial for ensuring the strength and safety of materials and components, especially when there is a risk of them breaking in a brittle manner.

1. Reduce Defects

To prevent brittle fractures, focus on making sure materials and components are free from any flaws. This means carefully checking the quality of materials during manufacturing and looking for any issues. Make sure that the way you cast or shape the materials is done correctly.

Afterwards, thoroughly inspect the materials to ensure they are defect-free. By doing this, you reduce the chance of weak spots or defects that might lead to brittle fractures.

2. Improve Material Toughness

To make materials less likely to break in a brittle manner, you can change the composition of the material or adjust how it is treated with heat. This can make the material more challenging, meaning it can withstand more strain and pressure without breaking. These changes can help reduce the sensitivity of the material to notches and imperfections that might lead to brittle fractures. By improving material toughness, you can ensure it is less likely to break suddenly.

3. Relieve Stress

Stress in materials can be like a ticking time bomb for brittle fractures. To prevent this, you can use stress relief techniques during manufacturing. This can involve processes like heating and cooling materials in a controlled way to release any built-up stress.

Properly cooling and handling materials can also help reduce hidden stress that could later cause brittle fractures. This step ensures that the manufactured parts are not under hidden stress that might lead to sudden breakage.

4. Choose the Right Materials

Picking materials that behave correctly under different temperatures is a critical step to prevent brittle fractures. You can do tests, like Charpy and Izod tests, to see how materials behave at various temperatures.

This helps select materials that remain flexible at the temperatures they will be exposed to in their application. If needed, you can modify the material’s composition and apply heat treatments to ensure it behaves as expected. By selecting suitable materials, you ensure they will not break suddenly under the conditions they are used in.

5. Avoid Brittle Structures

If possible, steer clear of microstructures within materials that tend to be brittle. Microstructures that are more ductile and less likely to break are better for critical applications. If you come across inherently brittle microstructures, like martensite, consider using processes to make them less brittle while maintaining their strength.

The approach guarantees that materials and parts retain the necessary properties to avoid the risk of brittle fractures. Making the right choices regarding materials and processing is essential to prevent inherently brittle structures.

Brittle fracture is one of several crucial topics covered in the comprehensive API 571 training program by PetroSync. This training delves into various aspects of materials and structural integrity, equipping you with the knowledge and skills needed to prevent brittle fractures and ensure the safety and reliability of critical systems in the industry.

Credit: tu-braunschweig

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.