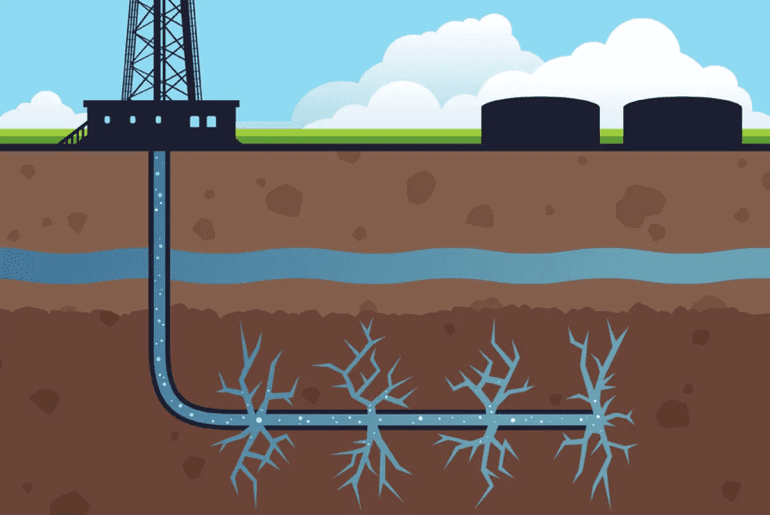

Hydraulic fracturing is a process that involves injecting high-pressure fluid into rock formations deep below the Earth’s surface. The fluid creates fractures in the rock, allowing trapped hydrocarbons—such as oil and gas—to flow more freely to the production well.

This technique has enabled the extraction of resources from unconventional reservoirs, such as shale formations, that were previously uneconomical to develop. Hydraulic fracturing has brought numerous benefits, including increased energy production and economic growth. However, it also presents environmental challenges, which have sparked intense debate.

What Is Hydraulic Fracturing?

Hydraulic fracturing, or fracking, is a well-stimulation technique used to extract oil and natural gas from deep underground formations. The process involves drilling a well and then pumping a mixture of water, sand, and chemicals into the rock at high pressure. This creates small cracks, or fractures, in the rock, enabling hydrocarbons to flow more freely.

The definition Hydraulic Fracturing highlights its role as a key driver of energy production. Without this method, vast reserves of oil and gas would remain untapped, limiting global energy supplies. Hydraulic fracturing meaning goes beyond just breaking rocks—it represents an innovative solution to meet growing energy demands.

Despite its importance, it is often misunderstood, making it essential to clarify what Hydraulic Fracturing entails.

What Is The Purpose of Hydraulic Fracturing?

The primary purpose of hydraulic fracturing is to enhance the productivity of oil and gas wells. By creating fractures in the rock, fracking increases the permeability of the reservoir, allowing more hydrocarbons to flow to the surface. This makes the extraction process faster, more efficient, and economically viable.

Moreover, has enabled access to previously untapped resources, such as shale gas and tight oil. These unconventional reserves have significantly boosted energy production, reducing dependence on foreign energy imports and enhancing energy security for many nations.

From an economic perspective, has been a game-changer. It has created jobs, supported local economies, and contributed to global energy markets. Industries reliant on oil and gas have flourished, thanks to the increased supply and affordability of these resources.

What Are The Problems with Hydraulic Fracturing?

While hydraulic fracturing offers numerous benefits, it is not without challenges. One major concern is its potential impact on the environment. Critics argue that the chemicals used in fracking fluids can contaminate groundwater supplies if not handled properly. Additionally, the disposal of wastewater from the process poses risks to local ecosystems.

Another issue is the significant water usage required for hydraulic fracturing. In regions facing water scarcity, the demand for millions of gallons of water per well can strain local resources. This has led to concerns about the long-term sustainability of the practice.

Seismic activity, or “induced earthquakes,” has also been linked to some areas.

These tremors, although generally small, have raised alarm in communities near fracking sites. As a result, the industry faces increasing pressure to address these environmental and social concerns.

Why Is Hydraulic Fracturing Banned?

Hydraulic fracturing has been banned in certain regions due to its perceived environmental and public health risks. Countries and states with stringent environmental policies have opted to prohibit fracking to safeguard their natural resources.

For example, concerns about groundwater contamination, air pollution, and seismic activity have prompted bans in parts of Europe, such as France and Germany. In the United States, some states, including New York, have also imposed bans or strict regulations on fracking.

Public opposition has played a significant role in these decisions. Many communities worry about the potential long-term consequences, including its impact on water quality, land use, and public health. These concerns have fueled debates about whether the benefits of fracking outweigh its risks.

Join PetroSync’s Comprehensive Training Program for Industry Professionals

Navigating the complexities of hydraulic fracturing requires a deep understanding of its technical, economic, and environmental aspects. PetroSync offers a comprehensive training program designed for industry professionals seeking to enhance their expertise in this critical area.

Our program covers a wide range of topics, including the fundamentals of hydraulic fracturing, advanced techniques, and best practices for minimizing environmental impact. Led by experienced trainers, the course provides valuable insights and practical knowledge to help you excel in your career.

Whether you’re a seasoned professional or new to the industry, PetroSync’s training program equips you with the skills and knowledge needed to stay ahead in the ever-evolving energy sector. Don’t miss this opportunity to advance your expertise and make a positive impact in your field.

Results-oriented and thorough SEO specialist with extensive experience in conducting keyword research, developing and implementing digital website promotion strategies and plans, managing campaigns to develop company websites in the digital world, excellent knowledge of marketing techniques and principles, and attentive strong attention to detail.