Welcome to our exploration of brittle fractures, a puzzling phenomenon for scientists and engineers. In this article, we will break down everything about brittle fracture, going from its definition to practical insights. Read on to get a complete understanding of this intriguing topic.

What Is Brittle Fracture?

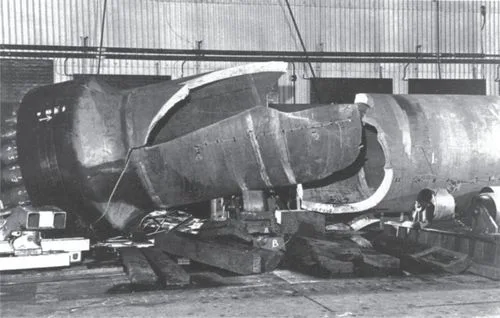

A brittle fracture refers to the sudden and rapid spread of a crack-like flaw in a material when it is subjected to stress. This type of fracture typically occurs with little to no evidence of the material’s ability to deform plastically. While brittle fractures are relatively rare, they can have severe consequences, making it essential to focus on their prevention in equipment and structural management strategies.

The factors contributing to brittle fractures include:

- The level of applied and remaining stresses in the component.

- The size of the initial flaw or defect.

- The material’s fracture toughness.

- Environmental conditions within the facility, particularly when ambient temperatures drop below the Minimum Design Metal Temperature (MDMT) of -20°F/-28°C.

What Is Brittle Fractures Assessment?

Brittle fracture assessment involves evaluating the risk and potential occurrence of brittle fractures in materials or structures. This assessment considers factors such as:

- The magnitude of applied and residual stresses

- The size of initial flaws or defects, the fracture toughness of the material, and

- The environmental conditions within a facility.

The goal is to prevent brittle fractures and ensure the safety and reliability of equipment and structures, particularly when exposed to low ambient temperatures.

When to Perform Brittle Fractures Assessment?

You should perform a brittle fracture assessment to check the risk of materials breaking suddenly. It’s necessary when you need to consider things like how much stress a part is under, any initial flaws, the strength of the material, and the environment it’s in. This assessment helps ensure safety, especially in cold conditions.

Brittle fracture assessments are essential for high-risk equipment and pipelines, even if they are relatively new, to prevent unexpected failures. Several situations may prompt the need for such an assessment:

1. Change in Process or Operating Conditions

If the equipment is being used for a different purpose or if there are changes in how it operates (e.g., optimizing startup or shutdown procedures), a brittle fracture assessment is crucial. One of the possible conditions is if a tank previously used for storing one type of chemical is repurposed to store a more volatile substance, the change in operating conditions could trigger the need for an assessment.

2. Process Hazards Review

If a review of the process reveals that metal temperatures are lower than expected, it is a red flag. This might occur during events like auto-refrigeration or operational upsets. This case may happen in a chemical plant. During an auto-refrigeration event, temperatures in a vessel unexpectedly drop due to the cooling effect of a chemical reaction. This could require a brittle fracture assessment.

3. Re-rating or Fitness-for-Service (FFS) for Other Damage

If there are concerns about other damage to the equipment and you are assessing its fitness for service, a brittle fracture assessment may be prudent.

For instance, if a piece of equipment has experienced corrosion, and you are assessing whether it is still fit for service, you would also want to consider the risk of brittle fracture.

4. Equipment Repairs or Alterations

Any repairs or changes to the equipment may impact its susceptibility to brittle fracture and should be evaluated. One possible scenario is when you have repaired a pressure vessel by welding, the welding process and its impact on the material’s properties need to be assessed.

How Is The Brittle Fractures Assessment Workflow?

The brittle fracture assessment process involves three different levels to determine the safety of pressure vessels, piping, and tankage:

1. Level 1 Assessment

This is the initial assessment and is based on specific industry codes. It includes testing and determining a material’s ability to withstand impact. At this level, a single value for the Minimum Allowable Temperature (MAT) is determined at the maximum operating pressure. More detailed analysis is required for further assessments.

2. Level 2 Assessment

Level 2 is more in-depth and divided into three methods. In the first method (Method A), equipment might not need further assessment if it operates within a safe range of pressure and temperature. In the second method (Method B), equipment can be qualified for continued use after passing a hydro test. The third method (Method C) qualifies equipment based on materials, operating conditions, and experience. Tankage has its separate assessment combining these three methods.

3. Level 3 Assessment

This level is for equipment that does not meet the criteria for Levels 1 and 2. It requires a thorough evaluation involving experts from various fields. A Level 3 Assessment typically uses a detailed fracture mechanics approach, looking at factors like stress, flaw size, and material toughness to assess the risk of brittle fracture.

In simple terms, these assessment levels help ensure equipment safety by thoroughly evaluating its ability to withstand brittle fractures. Depending on the assessment level, different criteria and tests are used to determine if the equipment is safe. This process is essential in industries where equipment reliability is critical.

The assessment process, as regulated under API 579 Fitness for Service, presents a methodical approach with varying levels of evaluation. These evaluations are essential for preventing unforeseen equipment breakdowns. By scrutinizing factors such as material strength, operational conditions, and resistance to impacts, industries can pinpoint and mitigate the potential hazards linked to brittle fractures. This approach not only averts accidents and costly repairs but, more crucially, upholds the welfare of personnel and the environment.

A comprehensive brittle fracture assessment serves as a safeguard against catastrophic events and also promotes the enduring integrity of equipment. It enables informed decision-making concerning the ongoing use of equipment, and guiding strategies for repairs, maintenance, or replacements.

The API 579 training offered by PetroSync can be your gateway to mastering the art of brittle fracture assessment in a comprehensive and industry-recognized manner. As we have seen, correct assessments are indispensable for ensuring the safety and integrity of critical equipment and structures. By enrolling in this training, you not only equip yourself with the knowledge and expertise necessary for accurate assessments but also open doors to a world of industry insights, networking, and professional growth.

Credit header image: TWI

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.