To really grasp the significance of porosity, we must consider how materials perform under stress. Porosity is the existence of voids or pores within a material, which can significantly modify its mechanical properties. Materials with high permeability, such as sponges or certain rocks, may have reduced strength and resistance to external forces as a result of the empty spaces.

Materials with reduced permeability have a higher density and strength. Permeability in a material can affect its weight, strength, thermal conductivity, and permeability. Furthermore, materials with high permeability are more likely to erode over time. Porous concrete, for example, can cause structural damage, despite the fact that permeability is required for fluid storage in oil reservoirs.

Understanding permeability and its impact on material performance is therefore crucial in the design and usage of materials in practical applications.

What Is Porosity?

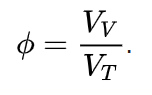

Porosity is refers to the proportion of pore volume about the overall volume of the rock or material and is typically expressed as a percentage. It is calculated as a fraction between 0 and 1, or as a percentage between 0% and 100%, representing the volume of voids relative to the total volume.

Measuring permeability tells us how much of the material is made up of these voids relative to its total volume. In some cases, permeabilitytests may specifically measure the “accessible void,” which is the void space accessible from the material’s surface.

Understanding permeability is important in various industries like geology, soil science, and materials engineering as it affects permeability, density, and other physical properties. Managing permeability properly is crucial for manufacturing, geological studies, and designing reliable materials and structures.

What Are Porosity Examples?

Porosity plays a vital role in finding and producing oil and gas. Rocks in the subsurface, like sandstones or carbonates, can have tiny spaces called pores, where hydrocarbons and fluids are stored. These porous rocks act as natural containers, holding valuable oil and gas underground. Geologists and reservoir engineers use special tools to measure the permeability.

In these rocks to figure out how much oil and gas they can potentially hold. The higher the permeability, the more likely it is to find significant amounts of oil and gas in these reservoirs, making it crucial for successful exploration and production. Another use of knowing the importance of permeability is during well cementing.

When drilling a well, engineers use cement to create a strong seal between the wellbore and surrounding rocks. This seal prevents fluids from moving where they shouldn’t and keeps the well safe. The rocks around the wellbore can be porous, with tiny spaces in them.

Knowing the permeability of these rocks is essential during cementing because it affects how well the cement sticks to the rocks. Engineers use this information to design the right cement mixture and ensure it creates a secure seal, making sure the well operates safely and effectively.

How To Calculate Porosity?

| Parameter |

Explanation |

|

o |

is porosity |

|

Vv |

is void volume |

|

VT |

is total volume |

What Are Some Porosity Measurement Methods?

Porosity can be measured using various methods, including:

1. Direct Methods

Direct methods involve physically measuring the void spaces in a material using core samples or specimens to calculate permeability directly.

2. Optical Methods

Optical methods use visual inspection and image analysis to estimate permeability by examining the material’s structure and identifying void spaces.

3. Computed Tomography Method

The Computed tomography method employs advanced imaging technology to create 3D models of the material, enabling precise measurement and visualization of permeability.

4. Imbibition Methods

Imbibition methods analyze how a material absorbs fluids, providing insights into its permeability and fluid transport characteristics.

5. Water Evaporation Method

The Water evaporation method measures the rate of water evaporation from a material, helping to assess its permeability and moisture-holding capacity.

6. Mercury Intrusion Porosimetry

Mercury intrusion porosimetry involves injecting mercury into the material’s pores under pressure to determine pore size distribution and overall permeability.

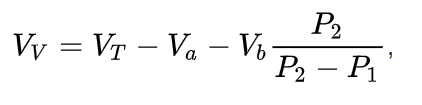

7. Gas Expansion Method

The Gas expansion method assesses permeability by measuring the expansion of gas introduced into the material’s void spaces. The volume of the pores is determined by applying the ideal gas law:

|

Parameter |

Explanation |

|

VV |

is the effective volume of the pores |

|

VT |

is the bulk volume of the sample |

|

Va |

is the volume of the container containing the sample |

|

Vb |

is the volume of the evacuated container |

|

P1 |

is the initial pressure in the initial pressure in volume Va and VV, and |

|

P2 |

is the final pressure present in the entire system. |

8. Thermoporometry

Thermoporometry uses thermal analysis to study the interaction between a material and gases, providing information about its permeability and surface area.

What Are The Types of Porosity?

There are several types of geologic porosity:

1. Total Porosity

Total porosity is the measure of empty spaces in a material, expressed as a percentage of the total volume. It impacts fluid storage, transmission, and material strength in various fields like geology and material engineering.

2. Connected Porosity

Connected porosity refers to linked void spaces in a material, allowing fluids like water, oil, or gas to flow through. This interconnectedness is crucial in geological formations, influencing hydrocarbon movement and groundwater flow.

3. Disconnected Porosity

Disconnected porosity consists of isolated void spaces that don’t form a continuous network, limiting fluid movement. It affects a material’s permeability and fluid storage potential, vital for assessing reservoir rocks in geology.

4. Effective Porosity

Effective permeability quantifies the fraction of interconnected void spaces contributing to fluid flow within a material. It plays a key role in hydrogeology and reservoir engineer, determining the volume of accessible voids controlling water, oil, or gas flow.

5. Trapped Porosity

Trapped porosity includes void spaces inaccessible or sealed off from fluid flow. It impacts fluid storage and flow behavior in geological formations and engineered materials, critical for assessing hydrocarbon reservoirs.

6. Vuggy Porosity

Vuggy porosity consists of irregularly-shaped voids or cavities in rocks formed by geological processes like dissolution or weathering. It significantly affects fluid flow in rocks, making it important for reservoir characterization and hydrogeology studies.

7. Vesicular Porosity

Vesicular porosity refers to circular voids or cavities formed by gas bubbles during volcanic processes. It affects the density and strength of volcanic rocks, influencing their engineering properties.

8. Dissolution Porosity

Dissolution porosity results from the removal of certain minerals or substances from a rock, leaving behind void spaces. This process, common in limestone, creates voids known as dissolution permeability, playing a role in forming features like caves and sinkholes in karst landscapes.

9. Moldic Porosity

Moldic porosity involves void spaces created by the dissolution of a shell or organic material within a rock. It results in molds or impressions, common in carbonate rocks, impacting their fluid flow characteristics.

10. Intergranular Porosity

Intergranular porosity refers to void spaces between grains or particles in a sediment or rock, enabling fluid flow. In sedimentary rocks like sandstone, it influences hydrocarbon storage and movement in reservoirs.

11. Intragranular Porosity

Intragranular porosity refers to void spaces within individual grains or crystals in a rock, affecting the material’s mechanical properties and fluid flow behavior.

12. Fracture Porosity

Fracture porosity includes void spaces resulting from fractures or cracks in rocks, serving as pathways for fluid flow in rocks with low permeability, essential in hydrogeology.

13. Micro Porosity

Microporosity consists of very small-scale voids or pores in materials, influencing permeability and surface area, observed in fine-grained rocks and engineered materials, impacting fluid flow behavior.

14. Primary porosity

Primary porosity refers to the original void spaces present in a material during its formation, impacting initial hydrocarbon storage and movement in reservoir rocks, common in sedimentary rocks.

15. Secondary porosity

Secondary porosity comprises void spaces formed after a material’s original formation, enhancing fluid storage and flow characteristics, significant in reservoir characterization and groundwater studies.

Why Porosity Is Important?

Understanding porosity holds great importance in the oil and gas sector, particularly in upstream operations. Permeability significantly impacts the upstream or drilling process by influencing the reservoir’s ability to hold and transmit hydrocarbons. It directly affects the flow of fluids within the rocks, dictating how easily oil and gas can be extracted.

High permeability allows for better storage and movement of hydrocarbons, enabling efficient production. Conversely, low permeability can hinder fluid flow, making extraction more challenging and less productive. Understanding permeability aids in selecting optimal drilling locations, predicting reservoir behavior, and designing effective production strategies.

All of which are crucial for successful upstream operations in the oil and gas industry. With permeability as a key factor, experts can enhance exploration efforts, optimize reservoir management, and improve hydrocarbon recovery efficiency, solidifying its role as a fundamental element in the oil and gas industry.

Elevate Your Career with PetroSync Training – Join Now

In PetroSync, you can delve into the concept of porosity within the broader context of well-completion and workover training. Our well-completion and workover training offers a range of in-depth subjects that collectively contribute to a holistic understanding of the oil and gas industry. Among these valuable topics is porosity – a fundamental aspect of reservoir characterization.

Our curriculum encompasses a series of meticulous subjects under the umbrella of well-completion and workover training, and porosity holds a crucial place within this framework. Enroll in Well Completion and Workover training and grasp not only the fundamentals of permeability but also recognize its pivotal role in the larger context of optimizing well completion and workover strategies with PetroSync!

Results-oriented and thorough SEO specialist with extensive experience in conducting keyword research, developing and implementing digital website promotion strategies and plans, managing campaigns to develop company websites in the digital world, excellent knowledge of marketing techniques and principles, and attentive strong attention to detail.