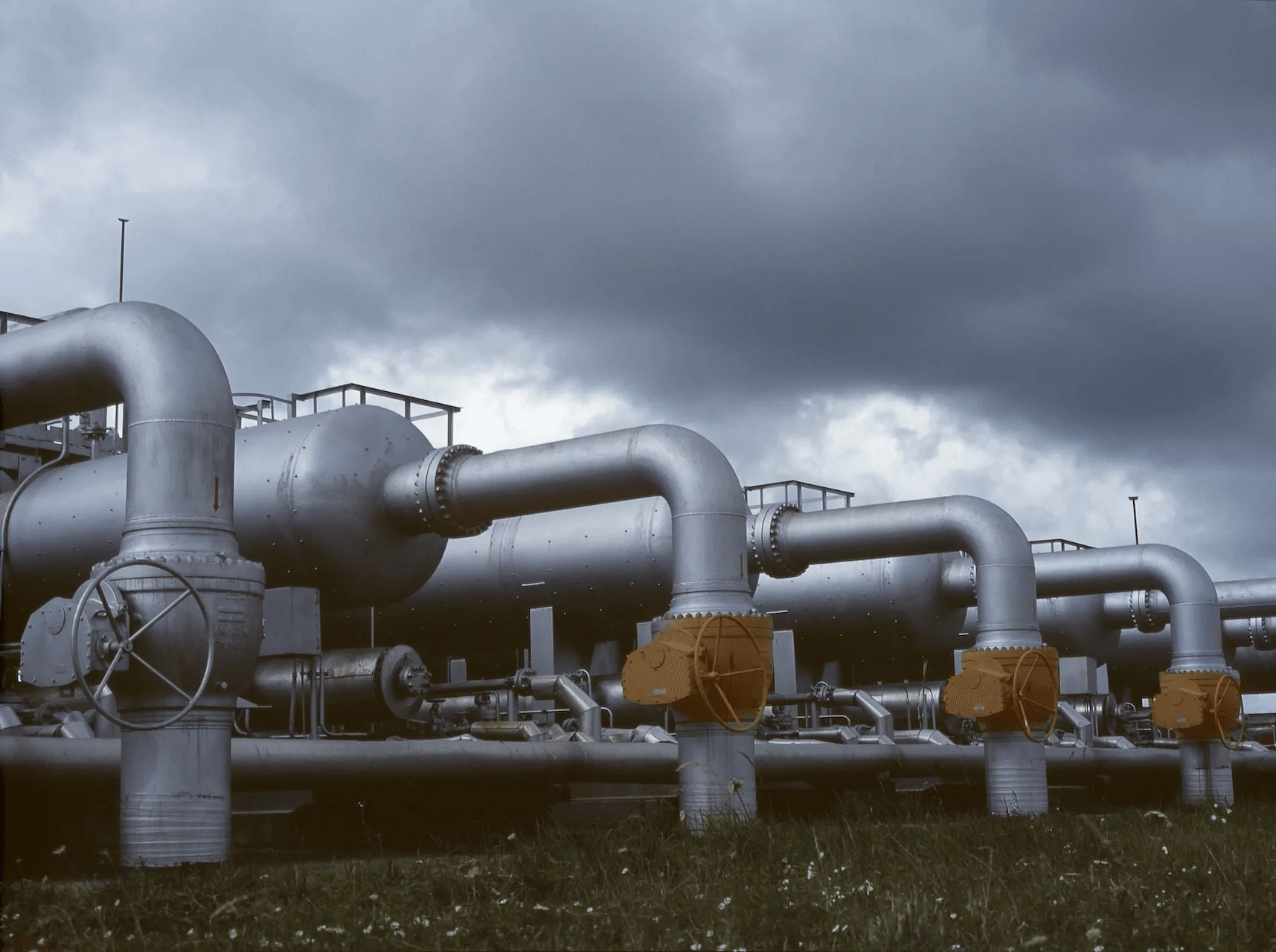

Pressure piping is a critical part of various industries, used for transporting fluids and gases under high pressures. It is essential for power generation, petrochemical plants, water supply, and industrial processes. Properly designing, installing, and maintaining pressure piping is crucial for safe and efficient operations.

This article will explore pressure piping, including its importance, regulations, inspection, repair, and key design considerations. Whether you’re an engineer or simply curious, this guide will provide valuable insights into this important aspect of modern industry.

What Is Pressure Piping?

Pressure piping is a system of pipes designed to hold fluids at high pressure. The piping is used for containing, transporting, and transmitting high-pressure gases and carrying vapor to a storage bank. Pressure piping comprises interconnected pipes, fittings, valves, and other associated components.

Pressure piping utilizes materials that possess the necessary strength and resistance to corrosion, ensuring they can endure the pressures and temperature changes they will encounter. Designing pressure piping involves taking into account various factors, including the operational pressure, temperature, flow rate, and the specific properties of the fluid or gas being transported.

What Is Pressure Piping Used For?

Pressure piping is versatile and suitable for a diverse range of pressure applications, including water supply, recycled water, irrigation, pressure sewerage, gas, and industrial applications.

In the petrochemical sector, pressure piping plays a crucial role in moving different chemicals and petrochemical products between processing units and storage tanks. Its design ensures it can withstand the corrosive properties of specific chemicals and maintain its integrity when subjected to high-pressure conditions.

Pressure piping is also employed in power plants to convey steam, water, and other fluids between various components of the power generation system. Its design is tailored to withstand high temperatures and pressures, ensuring the dependable and uninterrupted operation of power plants.

What Is The Standard for Pressure Piping?

The standard for pressure piping consists of established rules and specifications that regulate the design, construction, and installation of piping systems used for containing or transporting fluids or gases under pressure. Adhering to these standards is crucial to ensure the proper functioning and integrity of pressure piping systems. Some well-known standards for pressure piping include:

1. ASME B31.3

The ASME B31.3 code governs all aspects associated with pressure piping, including proper installation, design, and suitable inspection and maintenance techniques. ASME B31.1 offers comprehensive guidelines and standards for pressure piping in various industries, including oil and gas, petrochemical, and chemical plants.

The code contains several requirements that must be followed, including:

- Design conditions related to pressure, minimum and design temperatures, insulated and non-insulated components, both externally and internally.

- Observing design criteria such as pressure-temperature ratings for piping components, ratings during normal operation, tolerance for variations, and allowable stresses.

- Specific pressure design requirements for different types of pipes, connections, flanges, reducers, and other components.

- Criteria for components and their compatibility with the conveyed fluid.

- Guidelines for the flexibility and support needed in pressure piping systems.

- Specifications for the materials used in construction.

- Testing methods and criteria for acceptance, inspection, and examination.

The standard ensures that pressure piping systems are carefully engineered and constructed to endure the challenges of high pressures and temperature changes, while also taking into account fluid properties, flow rates, and environmental factors.

2. ASME PCC-2

ASME PCC-2 offers techniques for the repair of equipment, piping, pipelines, and related supporting equipment covered by ASME once they have been put in service. The standard revolves around detailed procedures to repair and restore the integrity of pressure piping systems that may have experienced damage or deterioration.

ASME PCC-2 places a strong emphasis on safety and quality in the repair process, ensuring that repaired pressure piping meets the necessary design and performance requirements. The standard covers a wide range of repair methods, including welding, bonding, mechanical repair, and non-destructive testing (NDT) techniques, offering engineers and technicians flexibility in choosing the most appropriate approach for specific repair scenarios.

3. API 570

API 570 covers inspection, rating, repair, and alteration procedures for metallic and fiberglass-reinforced plastic (FRP) piping systems and their associated pressure-relieving devices that have been put into operation.

API 570 is highly relevant to piping pressure as it specifically focuses on the inspection, evaluation, repair, and modification procedures for metallic and fiberglass-reinforced plastic (FRP) piping systems. It ensures that these piping systems and their associated pressure-relieving devices meet the required standards and are safe for operation.

What Is High-Pressure Piping?

High-pressure piping is gas fuel pressure piping that can withstand maximum working pressure greater than 10 bar or 1.0 MPa. Some organizations mention that the class of high-pressure is over class 300, equal to a pressure nominal of 50 bar.

A high-pressure piping system lacks a precise definition like categorized steels or chemicals. The classification of a line as high-pressure can vary between companies. For instance, one company may label a 250-psi line as high-pressure, whereas another might regard the same 250 psi as low-pressure.

What Are The Effects of Pressure on Piping Systems?

The influence of pressure on piping system design is considerable and can have various effects on the system’s operation and performance. Some notable impacts include:

1. Pressure Piping Design

- Pipe Thickness: Higher pressure requirements may necessitate thicker pipe walls to withstand the increased internal stresses. It also enhances the system’s rigidity.

- Material Selection: Pressure considerations influence the choice of materials to ensure they can safely handle the specified pressure levels.

- Flange and Valve Ratings: Higher pressures may require the use of flanges and valves with higher pressure ratings to maintain system integrity. As the flange rating increases, the thickness of flanges and valves also increases.

- Support and Tie-in Points: Increased pressure can lead to higher loads on pipe supports and tie-in points, requiring robust and well-designed support systems.

2. Safety Factors

Designers need to incorporate appropriate safety factors to ensure the system can handle pressure fluctuations and unexpected scenarios.

3. Cost

Higher pressure demands often result in increased costs due to the need for specialized materials, thicker components, and additional safety measures.

In summary, having a thorough understanding of pressure piping is highly important across various industries as it ensures the safe and reliable transportation of fluids and gases under high pressure. Knowledge of pressure piping, from design and installation to inspection and maintenance, is crucial to avoid accidents, leaks, and potential downtime associated with high-pressure systems.

PetroSync offers comprehensive training programs in ASME PCC-2, ASME B31.3, and API 570, providing you with the essential skills and knowledge needed in pressure piping. Our high-quality courses, led by experienced instructors, equip you with practical insights and keep them up-to-date with the latest practices, making PetroSync the top choice for pressure piping training in the oil and gas industry.

Whether ASME PCC-2 training, ASME B31.3 training, or API 570 training, join us today to enhance your expertise and advance your career in the dynamic world of pressure piping!

Credit: Pexels

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.