In asset-intensive industries such as energy, petroleum, and chemicals, risk management has become increasingly important over the years. It happens because practical risk-based inspection helps companies evaluate the calculation of cost and risk to make informed decisions regarding their equipment and facilities. One of the most recognized risk-based inspection (RBI) assessments many plants adopt is API 580 and API 581.

Table of Contents

ToggleWhat is API 580 – Risk-Based Inspection?

API 580 is a Risk-Based Inspection (RBI) standard developed by the American Petroleum Institute (API). It provides an approach to evaluate and assess the risk of pressure equipment and sets up an inspection program tailored to the individual risk profile.

The standard outlines the criteria for determining the inspection intervals and inspection methods. It also provides guidance on implementing a comprehensive management system for the inspection and maintenance of the equipment. The requirements for periodic evaluation and verification of the accuracy of the risk assessment also exist under API 580.

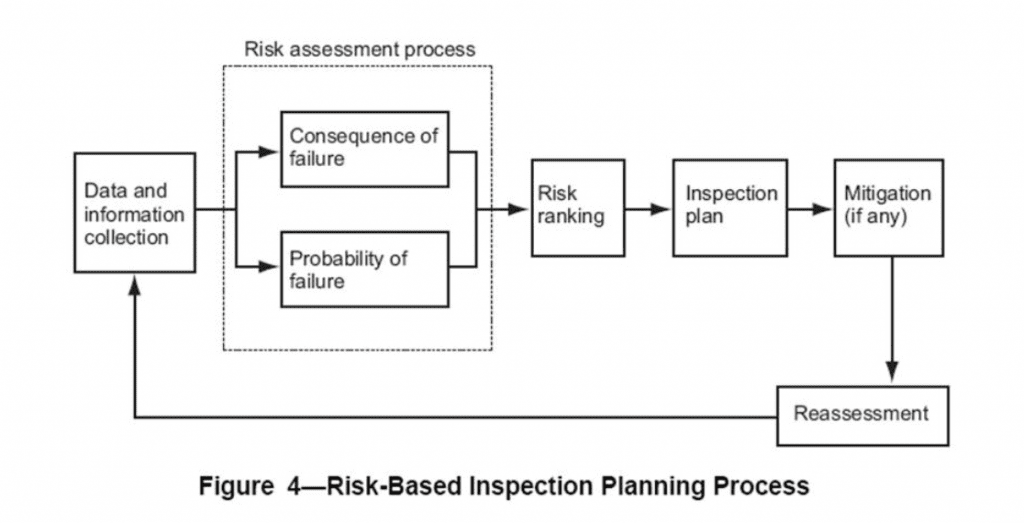

The main objective of this methodology is to identify, assess, and manage risks associated with equipment operation. By providing a framework for evaluating the probability and consequences of equipment failure, API 580 helps organizations make informed decisions regarding equipment inspection and maintenance. The practice is based on industry best practices and can be used as a foundation for developing an RBI program or as a reference for evaluating an existing program.

What Are API 580 Importance?

As a popular standard, the importance of API 580 are as follows.

1. Enhances Safety by Identifying High-risk Equipment.

API 580 enhances safety by pinpointing high-risk equipment, allowing for targeted maintenance and preventing potential accidents.

2. Optimizes Inspection Schedules, Reducing Downtime and Costs.

It optimizes inspection schedules, minimizing downtime and associated costs by focusing resources where they are most needed.

3. Supports Compliance with Regulatory Requirements.

API 580 supports compliance with regulatory requirements, ensuring that organizations adhere to safety and maintenance standards mandated by authorities.

What is API 581 – Base Resource Document?

API 581 is a Risk-Based Inspection (RBI) standard for setting up an inspection program for pressure equipment which is known as the base resource document standard. It provides a framework for setting up inspection plans that are tailored to the individual risk associated with different pieces of equipment.

This approach prioritizes and manages in-service equipment inspection programs by analyzing the likelihood and consequences of equipment failure. It aims to categorize equipment by its risks, prioritize inspection efforts, and guide risk mitigation strategies to reduce risks associated with operating processing facilities.

API 581 provides an approach for performing a risk assessment and determining an appropriate inspection interval and inspection method. The standard also guides how to set up a management system to inspect and maintain the equipment. API 581 has been developed based on the knowledge and experience of global practitioners of RBI and is intended to enable effective risk management.

What Are API 581 Importance?

As a popular recommended practice, the importance of API 581 are as follows.

1. Offers Advanced Technical Guidance for RBI Implementation.

API 581 provides advanced technical guidance for the successful implementation of Risk-Based Inspection (RBI) programs. It offers detailed instructions and best practices, ensuring that professionals have the necessary expertise to execute RBI strategies effectively.

2. Provides Quantitative Tools for Risk Assessment.

It also equips organizations with valuable quantitative tools for risk assessment. These tools enable a systematic and data-driven evaluation of equipment reliability and safety factors.

3. Enables A Deeper Understanding of Equipment Reliability.

By utilizing API 581’s resources, you can gain a deeper understanding of equipment reliability. This comprehensive approach fosters insights into the performance of assets.

What Is The Difference Between API 580 and API 581?

Though API 581 complements the existence of API 580, they actually provide different guidelines. API 580 focuses more on risk-based inspection, while API 581 focuses on asset integrity management by measuring through calculation.

| Parameter | API 580 Risk-Based Inspection | API 581 Risk-Based Inspection Technology |

| Scope | RBI for fixed equipment in the refining and petrochemical industries. | RBI for a broader range of equipment and industries with some adjustments and extensions. |

| Focus | RBI guidelines on managing risk on an equipment level. | Quantitative RBI methods like PoF and CoF calculation to support the minimum guidelines presented in API 580 |

| Approach | Qualitative | Quantitative |

| Editions | API 580 has been updated to a 3rd edition in 2016. | API 581 has been updated to a 3rd edition in 2016. |

| Coverage |

|

|

FAQs about API 580 – API 581

Below are some FAQs about API 580 and API 581 differences:

What Is The Primary Goal of API 580 – API 581?

API 580 and API 581 aim to assess and manage the risks associated with equipment and assets in various industries, with a focus on preventing failures and enhancing safety.

Are API 580 – API 581 Mandatory for All Industries?

While API 580 and API 581 are not mandatory for all industries, they are highly recommended, especially in sectors where equipment integrity is critical for safety and operational efficiency.

How Often Should Risk Assessments Be Conducted Following The Standard?

The frequency of risk assessments varies depending on the industry and equipment type but is generally recommended at least annually.

Can API 580 – API 581 Be Applied to Older Equipment?

Yes, API 580 and API 581 can be applied to both new and existing equipment to assess and manage risks effectively.

How Can Organizations Get Started with The Standard?

With a solid understanding of RBI performed by the proficient RBI team, organizations can optimize their inspection efforts for each plant equipment while minimizing the risk of equipment failure caused by relevant damage mechanisms.

Organizations interested in implementing API 580 API 581 should begin by familiarizing themselves with the standards and seeking guidance from experts in the field.

Enrolling in API 580 and API 581 training is essential for those looking to make a career in the oil and gas industry. This combined training covers a wide range of topics such as safety, risk analysis, inspection effectiveness and planning, damage mechanism, and determination of PoF.

With API 580 and 581 – Risk-Based Inspection & Base Resource Document, attendees can demonstrate their skills and knowledge to employers, increase their earning potential, and obtain credentials for the industry. Furthermore, the certification can improve safety and efficiency on the job and open up better career opportunities.

PetroSync combines the discussion of API 580 and API 581 courses to provide a more efficient and cost-effective learning experience, allowing professionals to learn the material in a comprehensive and integrated manner. Join our 5-day training and gain the latest industry knowledge with PetroSync!

Header image source: Freepik.com

Reserve Your Training Seat!

Enhance your skills with the latest industry knowledge. Kickstart your career growth with PetroSync training today!

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.