In the dynamic world of the oil and gas industry, it’s essential to keep yourself updated on the latest rules and practices. This article serves as your primary source for understanding the API 581 latest edition. API 581, also referred to as the Risk-Based Inspection (RBI) Methodology standard, plays a crucial role in ensuring the safety and dependability of equipment in the oil and gas sector. Let’s dive deeper into this important document.

What Is The Latest Edition of API 581?

API 581, known as Risk-Based Inspection Methodology, is a set of guidelines created and released by the American Petroleum Institute (API). These guidelines offer quantitative methods for risk-based inspection (RBI), aligning with the basic principles outlined in API 580. The first version of this guideline was issued in the year 2000, and the most recent 3rd Edition became available in April 2016.

By integrating the principles of RBI outlined in API RP 581 with practical assessments like those carried out in the case, the industry can optimize asset management, reduce risks, and enhance overall operational efficiency.

What Are The Key Features of API 581?

API 581, the Risk-Based Inspection (RBI) standard, is a comprehensive set of guidelines created by the American Petroleum Institute (API) to enhance safety and reliability in the oil and gas industry. Its main features include:

1. Risk Evaluation

API 581 employs advanced techniques to assess risks to equipment integrity, considering factors like corrosion, material wear, and operational conditions. This helps identify potential issues and critical areas.

2. Inspection Planning

API 581 assists in creating detailed inspection plans that prioritize tasks based on risk, reducing downtime and costs.

3. Data-Driven Decisions

The standard promotes informed decision-making by using historical and real-time data for inspections, improving overall efficiency.

4. Regulatory Compliance

API 581 often aligns with industry regulations, ensuring companies meet safety and reliability requirements.

5. Versatility

It’s adaptable and applicable across various equipment types and industries, catering to different company needs.

6. Technology Integration

The latest edition encourages using modern tools like data analytics and predictive modeling for more effective inspections.

What’s New in the API 581 – Latest Edition?

The API 581 latest edition, like its predecessors, is a product of extensive research and industry feedback. It incorporates the following key updates:

1. Enhanced Risk Analysis

The latest edition refines risk analysis methodologies, making them even more robust and reliable.

2. Integration with Technology

It embraces the use of cutting-edge technology, such as data analytics and predictive modeling, to enhance inspection strategies.

3. Expanded Scope

The latest edition widens its scope to cover a broader range of equipment types and industry applications.

What’s The Most Significant Update in The API 581 – Latest Edition?

The loss of material from a vessel or pipe can happen on the inner or outer surfaces, either when insulation is present or not. According to the API RP 581 classification, this change affects three mechanisms:

- Internal Thinning

- External corrosion in ferritic components

- Corrosion under insulation in ferritic components

It is important to keep in mind the formula used to figure out the chance of an equipment item failing (Pf) due to a specific type of damage within the API 581 method.

Detailed formula:

- gff is the generic failure frequency

- FMS is the management systems factor

- Df (t) is the damage factor

What Is The Case Study of RBI Implementation in The Industry?

In the case study run by Siswantoro and Priyanta, engineers checked the Condensate Separator 10V2102 and Condensate Storage Vessel 10V2103 while they were running normally. They collected important information like what kind of equipment they were, how they fit into the overall system, what they were made of, past inspection reports, what kind of stuff they held, how they were built, and their safety features.

After the study, they found that both the Condensate Separator 10V2102 and Condensate Storage Vessel 10V2103 were in the low-risk category. The key highlight of the RBI implementation in the case study is that it successfully identified both the Condensate Separator 10V2102 and the Condensate Storage Vessel 10V2103 as having a low-risk status.

This assessment was based on a thorough analysis of various data points, including equipment details, inspection history, and safety features. Additionally, the inspection intervals were found to exceed the standard recommendations, providing confidence in the equipment’s reliability. This outcome demonstrates the effectiveness of RBI in optimizing inspection schedules and ensuring the safety of critical assets.

What Are The FAQs About API 581 Latest Edition?

1. Where Can I Access the API 581 Latest Edition?

You can access the API 581 latest edition on the official website of the American Petroleum Institute (API).

2. Are There Training Programs Available for API 581 Implementation?

Yes, PetroSync offers API 580 & API581 training program to help you understand and implement the standard effectively. Consider enrolling your team for comprehensive training with us!

3. Can API 581 Be Applied to Offshore Equipment?

Yes, API 581 can be applied to both onshore and offshore equipment, making it versatile for various industry applications.

4. Is API 581 Suitable for Small-Scale Companies?

API 581 can be tailored to suit the needs of both large-scale and small-scale companies. Its flexibility allows for efficient risk-based inspection regardless of the company’s size.

In the ever-changing landscape of the oil and gas industry, API 581 continues to stand as a foundation for preserving equipment integrity and safety. The most recent edition introduces significant enhancements, rendering it an indispensable tool for industry experts. By adopting the risk-based inspection strategies laid out in API 581, companies can streamline their operations, mitigate risks, and prolong the lifespan of their valuable assets.

To support you in effectively implementing these methodologies, PetroSync provides comprehensive training programs in API 580 and API 581. This course equips you with the knowledge and skills needed to successfully apply the principles outlined in these standards, ensuring the safe and efficient management of equipment in the oil and gas sector. Reserve your training spot and master the Risk-Based Inspection skill with PetroSync!

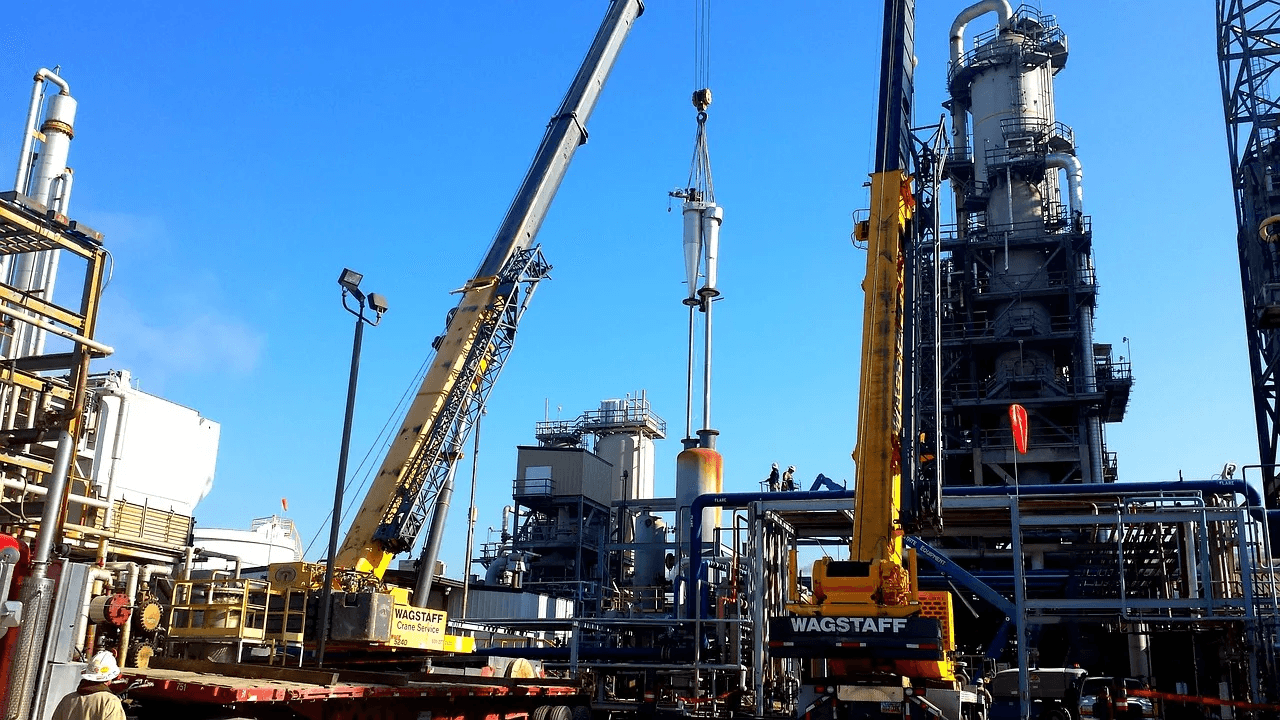

Credit: Pixabay

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.