Piping systems are essential for industries, as they transport fluids and gasses crucial for various processes. Whether in oil refineries or chemical plants, pipes are the backbone of industrial operations worldwide. However, designing these systems is not as straightforward as it seems. It involves understanding piping classes and specifications, which determine how pipes are designed and classified. In this article, we will explore why knowing about piping classes is vital for engineers and designers.

What Are Piping Classes?

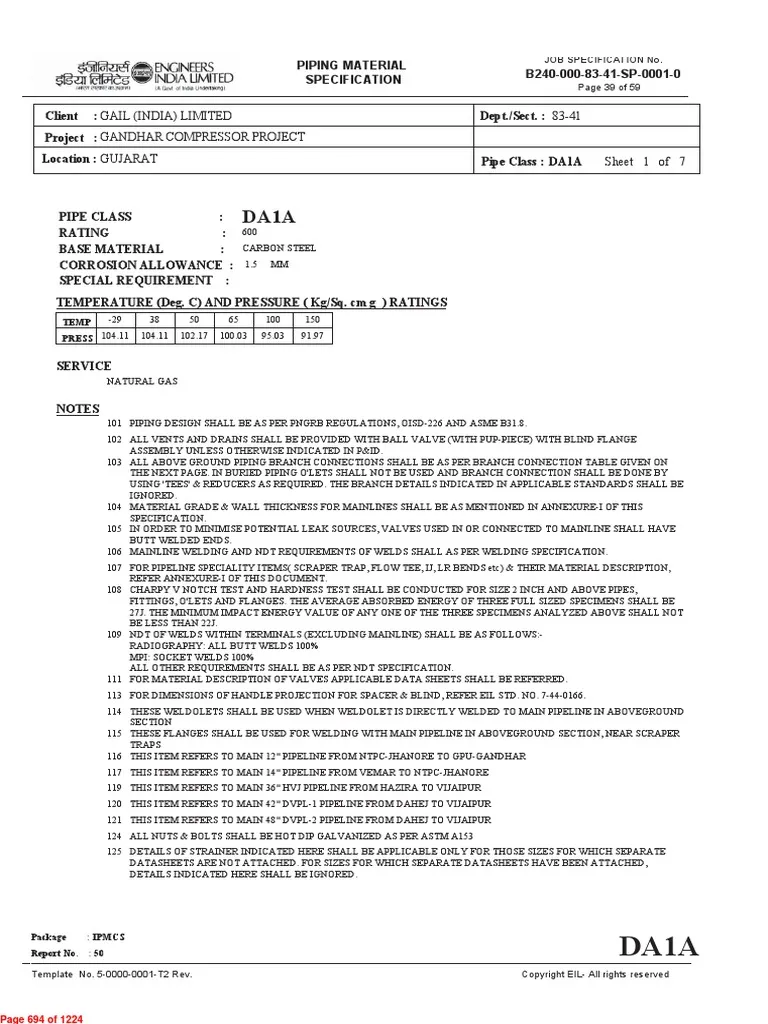

Piping classes is essentially a document that contains the definition of pipes and its related components to be used on a specific pressure or temperature condition. They follow the standardized specifications that outline the design, construction, materials, and testing requirements for piping systems used in various industries such as oil and gas, petrochemicals, and power generation.

The standardized specifications ensure consistency and quality across different piping projects. They define parameters like pipe size, wall thickness, material composition, and pressure ratings to ensure the safe and efficient operation of piping systems. Piping classes help engineers, designers, and fabricators understand the specific requirements for each component of a piping system, facilitating proper installation and maintenance.

What Do Piping Classes Consist of?

A piping class usually includes the following:

1. Process Design Conditions

Piping classes typically include information about the process design conditions, which outline the specific parameters under which the piping system will operate. This includes details such as the fluid type, temperature, pressure, flow rates, and any other relevant process requirements.

Understanding these design conditions is crucial for selecting the appropriate materials, sizing the pipes correctly, and ensuring the overall integrity and performance of the piping system.

2. Corrosion Allowance

Piping classes also specify the corrosion allowance, which is an additional thickness added to the pipe wall to account for potential corrosion over the system’s lifespan. Corrosion can weaken pipes and compromise their integrity, leading to leaks or failures.

By including a corrosion allowance in the design, engineers can ensure that the piping system remains structurally sound even in corrosive environments, extending its service life and reducing the risk of unplanned maintenance or downtime.

3. List of Piping Components

Piping classes provide a comprehensive list of all the components required for the piping system, including pipes, fittings, valves, flanges, and other accessories. This list ensures that all necessary parts are specified and accounted for in the design and construction of the piping system. Each component is selected based on factors such as material compatibility, pressure and temperature ratings, and the specific requirements of the process being served.

4. Branch Table

The branch table in piping classes details the various branch connections that may be required in the piping system, including tees, reducers, and other types of junctions. This table provides information such as the size, type, and location of each branch connection, helping to ensure proper configuration and layout of the piping system.

By specifying branch connections in advance, engineers can optimize the design for efficient fluid flow and minimize the risk of pressure drops or other performance issues.

5. Special Assemblies

Piping classes may also include specifications for special assemblies or configurations that are required for specific applications or operating conditions. These could include things like expansion joints, strainers, filters, or other specialized components that are necessary to meet the unique needs of the process or facility. By incorporating these special assemblies into the piping design, engineers can ensure that the system operates safely and efficiently under all foreseeable circumstances.

6. Support Notes

Lastly, piping classes typically include support notes that guide the installation, maintenance, and support of the piping system. This may include information on recommended support spacing, methods for anchoring and bracing the pipes, and procedures for inspecting and maintaining the system over time. Proper support and maintenance are essential for ensuring the long-term reliability and performance of the piping system, and the support notes help to ensure that these requirements are met.

Why Are Piping Classes and Specifications Important?

Here are why piping classes and specifications important

1. Customization and Special Requirements

Piping classes and specifications allow purchasers to incorporate specific requirements tailored to the design and service conditions of their project. This customization ensures that the piping system meets the unique needs and standards of the particular application, enhancing performance, reliability, and safety.

2. Ensuring Compliance and Quality

By specifying requirements in the piping classes and specifications, it becomes mandatory for the product to meet these standards. This ensures that the piping components are manufactured and installed according to industry regulations and best practices, guaranteeing compliance with safety, environmental, and performance standards.

3. Streamlining Engineering Processes

Having predefined piping classes and specifications streamlines the engineering process by providing clear guidelines and standards for the design, procurement, fabrication, and installation of piping systems. This reduces the risk of errors, delays, and rework during the project lifecycle, resulting in cost savings and improved efficiency.

4. Utilizing Established Standards

Oil and gas facilities often utilize established specifications from reputable companies or develop their own during the front-end engineering and design (FEED) stage. These specifications, often derived from industry leaders like Shell, Bechtel, EIL, and Chevron, provide a reliable framework based on proven practices and industry expertise, ensuring consistency, quality, and interoperability across projects.

In summary, piping classes and specifications play a vital role in ensuring the customization, compliance, quality, and efficiency of piping systems in various industries, including oil and gas. By incorporating specific requirements, adhering to established standards, and streamlining engineering processes, they contribute to the safe, reliable, and cost-effective operation of facilities and infrastructure.

What Is Class A and Class B Pipe?

Class A and Class B pipes are labels that describe how much pressure and heat a pipe can handle. The key difference between them is their ability to withstand pressure and temperature, as well as the thickness of the pipe walls.

Class A pipes have lower pressure-temperature ratings compared to Class B pipes. Typically, Class A pipes are suitable for applications with low pressure and low temperature, whereas Class B pipes are used in situations requiring high pressure and high temperature.

The wall thickness of Class A pipes is lesser than that of Class B pipes. This distinction arises from the differing pressure and temperature loads each class is designed to withstand. Class A pipes, handling lower pressure and temperature loads, require thinner walls for adequate strength, while Class B pipes, designed for higher pressure and temperature loads, necessitate thicker walls.

To sum up, the primary differences between Class A and Class B pipes are their pressure-temperature ratings and wall thickness. Class A pipes serve low-pressure, low-temperature applications, whereas Class B pipes cater to high-pressure, high-temperature environments.

What Are Class 1 and Class 2 Pipes?

According to the International Maritime Organization (IMO), Class 1 pipes are typically needed for substances that can cause corrosion. Class 2 pipes, on the other hand, can also handle corrosive materials, but extra precautions are taken to prevent leaks and minimize any potential harm if a leak does occur.

These precautions might include using pipe ducts, shields, or screens to contain leaks and prevent damage to nearby areas. Class 3 pipes are not suitable for use with corrosive substances. When selecting materials for piping systems that will carry corrosive substances, special attention must be given to ensure they are suitable for the task.

What Are The International Standards for Piping?

As piping holds vital role across industries, there are quite a lot standards discussing about piping:

1. ASME B31.3

ASME B31.3 is a widely recognized international standard developed by the American Society of Mechanical Engineers (ASME). It provides guidelines for the design, construction, and maintenance of process piping systems. This standard covers various aspects such as materials, fabrication, inspection, testing, and safety requirements for piping used in industries such as oil and gas, chemical, petrochemical, and power generation.

2. API 570

API 570 is another prominent international standard established by the American Petroleum Institute (API). It focuses specifically on the inspection, repair, alteration, and rerating of in-service piping systems used in refineries, chemical plants, and other process industries. API 570 outlines the requirements for maintaining the integrity and safety of piping systems throughout their lifecycle, ensuring compliance with industry regulations and best practices.

3. ASTM A106

ASTM A106 is a widely used international standard developed by the American Society for Testing and Materials (ASTM). It specifies seamless carbon steel pipe for high-temperature service in industries such as oil refineries, petrochemical plants, and power plants. ASTM A106 covers dimensions, mechanical properties, and testing requirements for seamless carbon steel pipes used in high-temperature and high-pressure applications.

These international standards provide a framework for ensuring the quality, safety, and reliability of piping systems used across various industries worldwide. Adhering to these standards helps to promote consistency, interoperability, and compliance with regulatory requirements, ultimately contributing to the efficient and safe operation of industrial facilities and infrastructure.

Understanding piping classes and specifications is essential for piping engineers and designers. These standards provide clear guidelines for designing, constructing, and maintaining piping systems, ensuring they meet industry regulations and function effectively. By following these standards, engineers can enhance the safety, reliability, and efficiency of piping systems, benefiting industrial operations.

Moreover, participating in training programs like ASME B31.3 training and API 570 training offered by PetroSync is highly beneficial for piping professionals like you. Our programs offer practical knowledge and skills relevant to piping system design, inspection, and maintenance, aligning with international standards. Engaging in these training courses allows you to gain valuable insights, learn industry best practices, and advance your career in piping engineering. Don’t miss the chance to expand your expertise by enrolling in ASME B31.3 and API 570 training with PetroSync.

Credit header image: Vecteezy

SEO specialist by day, fact-checker by night. An avid reader and content writer dedicated to delivering accurate and engaging articles through research and credible sources.